In our 300 m2 laboratory and pilot plant facility we offer preliminary tests in vitro and/or on different production units, to demonstrate feasibility and serve as a basis for optimization. Examples include platform chemicals, monomers synthesized from renewable resources, industrial biotechnology and recycling of plastics.

Reaction and separation techniques

Reaction techniques

Our work focuses on the development and optimization of environmentally-friendly, sustainable production processes for batch and continuous chemical engineering approaches.

The influence of process parameters on various reactions is investigated and evaluated statistically. These parameters include pressure, temperature and residence time, as well as the use of catalysts, other fluids and oxidation or reduction agents. One example is the breakdown of fats and oils: the monomers obtained can be used to synthesize biobased polymers.

In particular in the field of biorefineries and the use of renewable raw materials we have extensive experience and know-how. Emphasis is placed on the recovery of lignin, hemicelluloses and celluloses from wood fibers (lignocelluloses) using the organosolv process, and on the breakdown of lignins into phenol fractions. Additional research topics include the synthesis of sugar-derived products such as 5-HMF (5-hydroxymethyl furfural) and furan dicarboxylic acid.

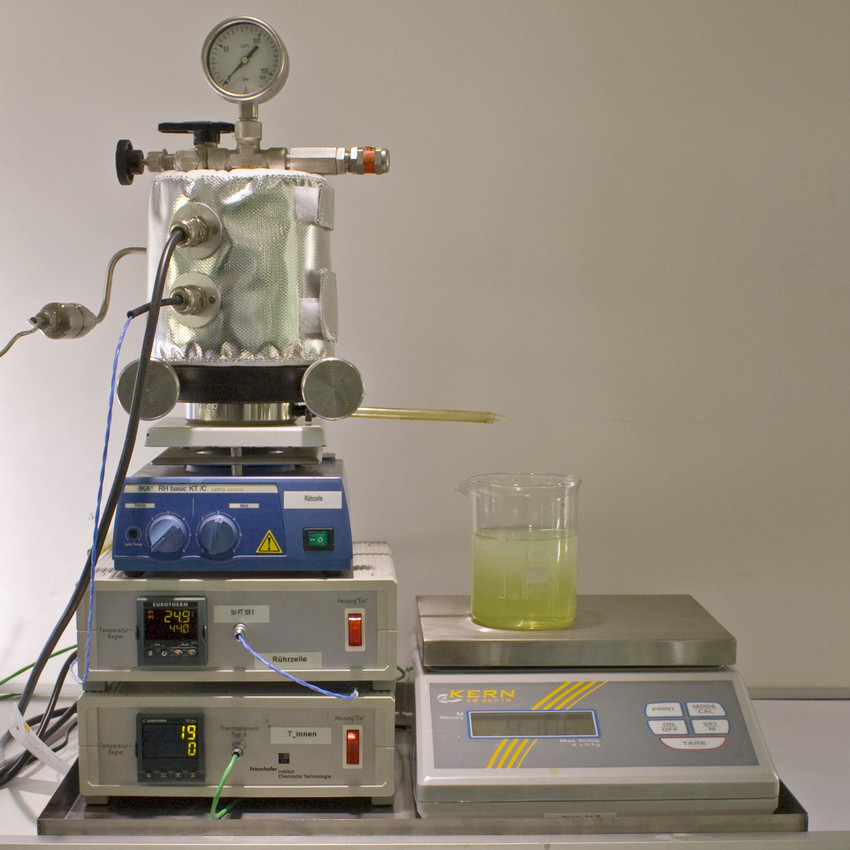

In a variety of high-pressure processing units the influence of process parameters on various reactions is investigated. These include pressure, temperature and residence time, as well as the use of catalysts, other fluids and oxidation or reduction agents. The batch reactors range in volume from 0.1 to 13 liters, at temperatures up to 400 °C and pressures up to 1000 bar. The continuous plants have pressures of up to 350 bar at temperatures up to 400 °C.

Separation techniques

Thermal processes, in which separation occurs due to a phase change, are used in various technology systems within our institute:

- Extraction involves, for example, separation using carbon dioxide in the supercritical phase or in aqueous solutions. One example of extraction using carbon dioxide is the extraction of organic binders from components or the extraction of phosphate from sewage sludge using carbonated water.

- Crystallization is useful for achieving particularly high purities above 99.9 %. When mixtures of substances cannot be sufficiently separated due to their solubility properties, similar boiling points or azeotropy, crystallization is an alternative method to achieve the desired separation.

- A range of equipment is available for the concentration of individual components via rectification and distillation. For example, the research group is currently investigating the fractionation of tall oil using high-temperature rectification, in order to separate resin and fatty acids.

Supercritical fluids, water and CO2 are a specialized topic in the field of thermal processes.

The use of supercritical carbon dioxide (sc-CO2) has numerous advantages compared with other processes, which generally involve solvents. It enables recovery of the extraction medium in a closed-loop process, through fractionated sedimentation of the extract. Supercritical CO2 is also chemically inert with no risk of explosion. Beside its gas-like viscosities, fluid-like densities and very good transportation properties, an advantage of supercritical CO2 is its capacity to dissolve a wide variety of organic components.

The debinding of components, the extraction of plant-based active ingredients and the degreasing of surfaces are just a few examples of applications using supercritical CO2 as a solvent. When highly exothermic reactions, or reactions with oxidizing materials, are carried out, the reaction in supercritical CO2 can be an attractive alternative to conventional syntheses.

Supercritical water (water above 374.12 °C and 221.2 bar) has very different properties to water under familiar conditions. In the supercritical state it can serve, for example, as a solvent for organic compounds, or for the decomposition of electronic waste.

Mechanical methods, which rely on the use of gravity, centrifugal force, pressure, vacuum or pure particle size are used by the research group in the form of filtration and membrane technology.

Membrane technology is a powerful alternative to conventional separation processes. It can separate organic substances, salts and fine solids from water. It thus opens up new possibilities and can replace or be combined with existing technologies, such as evaporation or chemical processes, due to its high economic efficiency. An effective hybrid process can be obtained, combining the advantages of several techniques.

In the technical center, eight systems are available for a wide variety of investigations. A large number of flat sheet membranes (MF, UF, NF, oNF, RO) from various suppliers are available for feasibility studies.

The 2 typical characteristics of all membrane separation processes are:

- Membrane separation processes involving a purely physical separation, i.e. the components to be separated are not changed thermally, chemically or biologically. It is therefore possible to recover and reuse the components of a mixture.

- Membrane processes have a modular design and can therefore be adapted to any capacity on a large scale.

Examples of projects

Increasing raw material prices and the depletion of fossil resources have led to an increased trend towards sustainable production processes and the use of renewable raw materials. Our research into reaction and separation techniques therefore includes the recovery and purification of components from sustainable raw materials and the recovery of high-value materials or the removal of hazardous substances from waste streams.

Examples of current projects:

Era-min 2: Joint project SUPERMET

Selection of previous projects:

- BioKompass: Communication and Participation for the Societal Transformation to the Bioeconomy image & partners

- LignOx: Lignin oxidation to obtain high-quality functional compounds

- Optigär: Material recycling of hydrolysis products from two-stage biogas plants

- LCB: Fractionation of biomass to recover lignin, hemicellulose and cellulose

- Synthesis of sugar-derived products such as HMF or furfural

- Splitting of lignin into phenolic building blocks and recovery of solvent

- Purification of product mixtures and waste water streams using membrane processes

- Particle foaming of plastics in supercritical CO2

- CO2 extraction of hazardous substances and production residues, and of active ingredients and flavors

- Recovery of pure fatty acids, resin fractions and sterols from tall oil

- Separation of fats and oils

- Hydrogenation of sugars to sugar polyols, used as crosslinking agents for polyurethane systems

- Waste water oxidation: Removal of organic matter from HTC process and other waste water

- Complete processing of liquid manure

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT