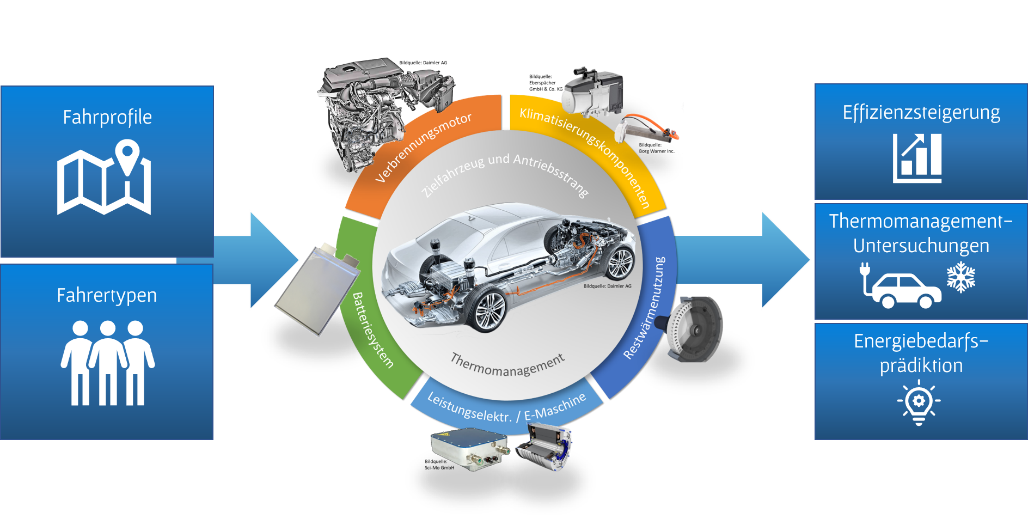

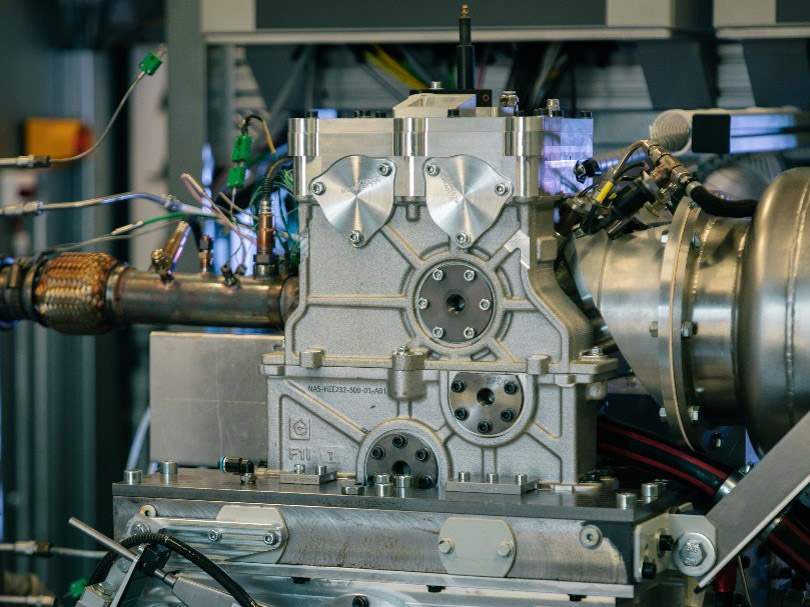

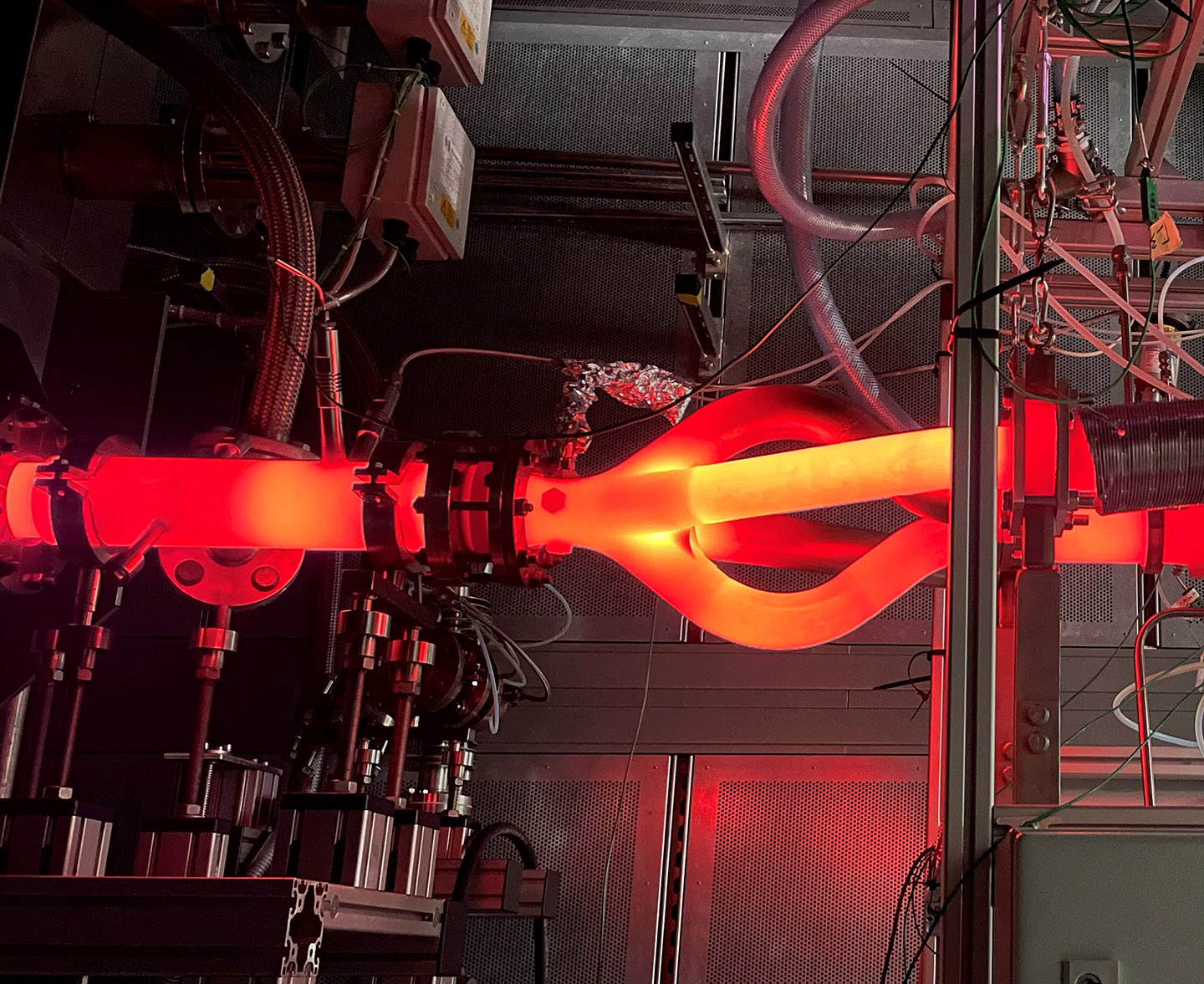

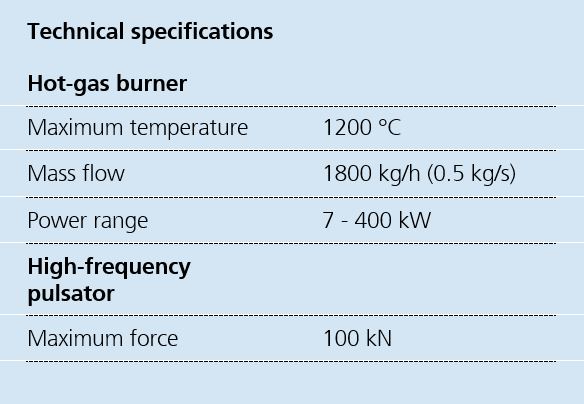

In the research group for testing and validation, components and systems for new drive technologies are evaluated using cutting-edge test and measurement equipment. The objectives of the tests are to characterize and evaluate the components and systems in terms of their functionality, efficiency, emissions and service life.

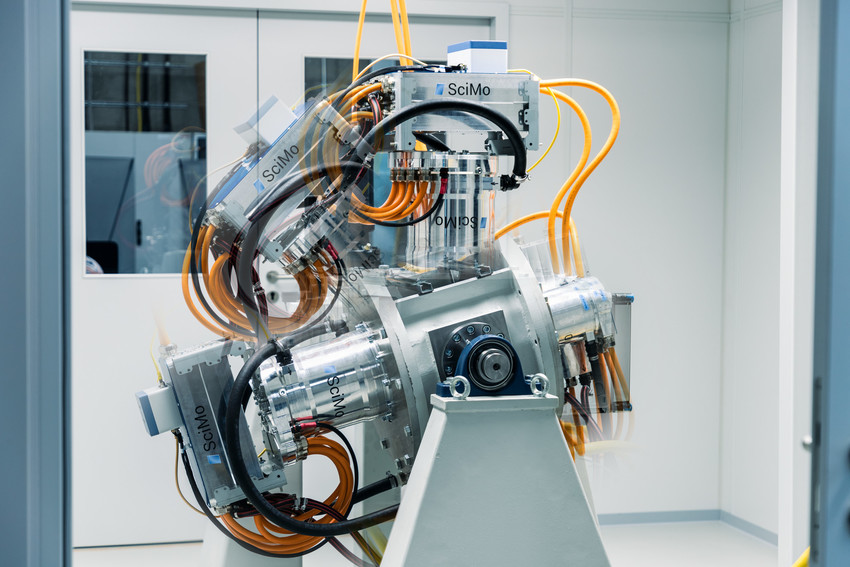

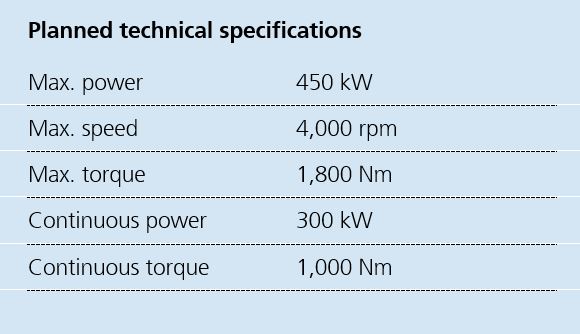

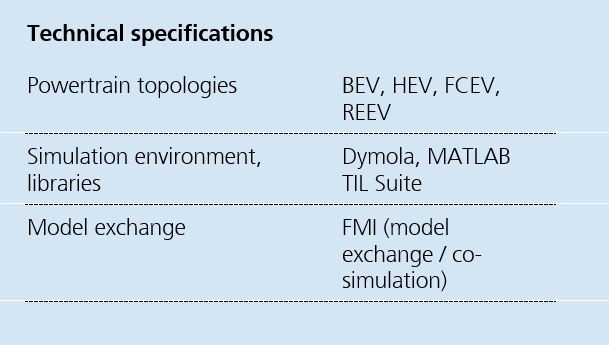

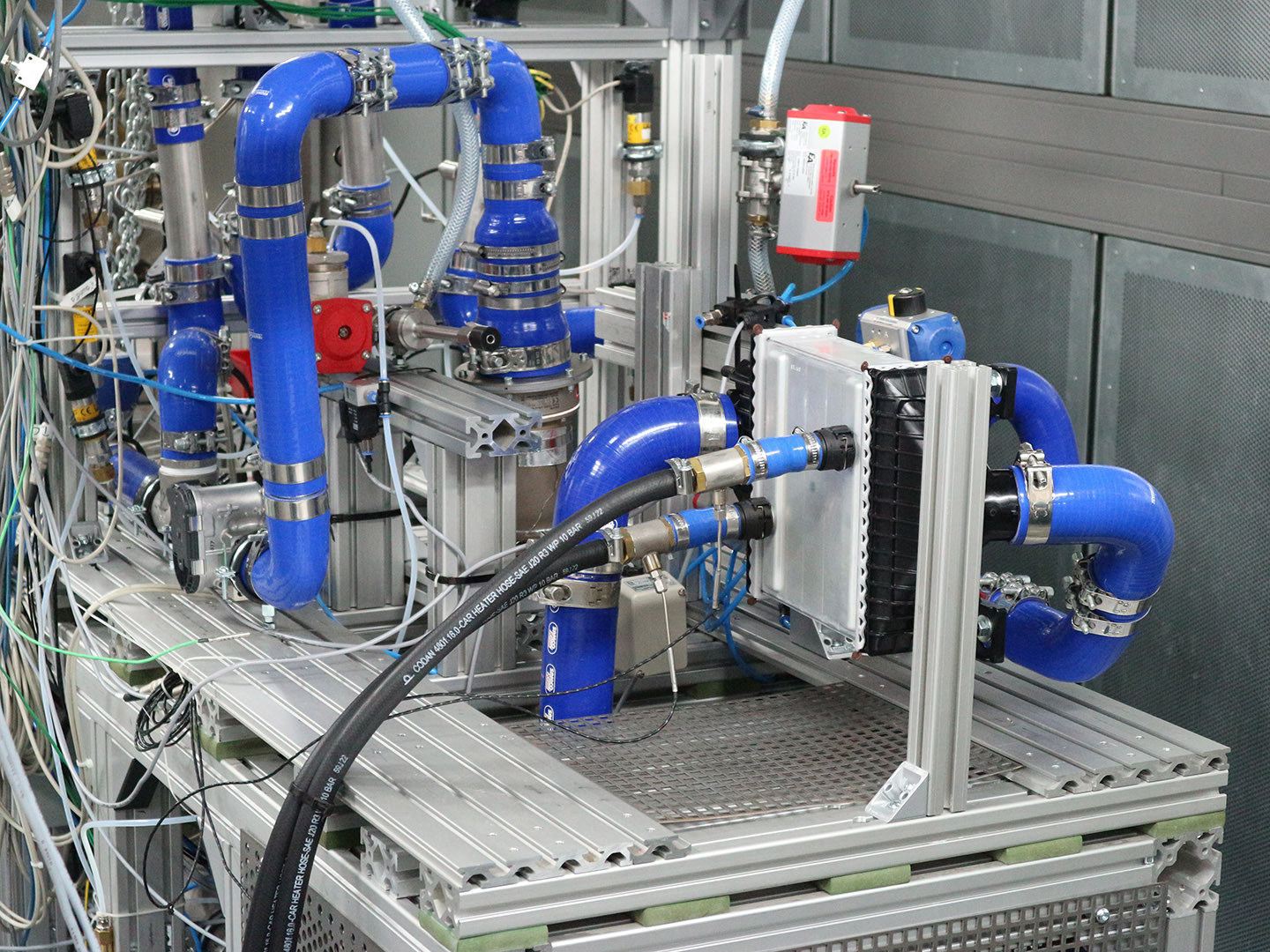

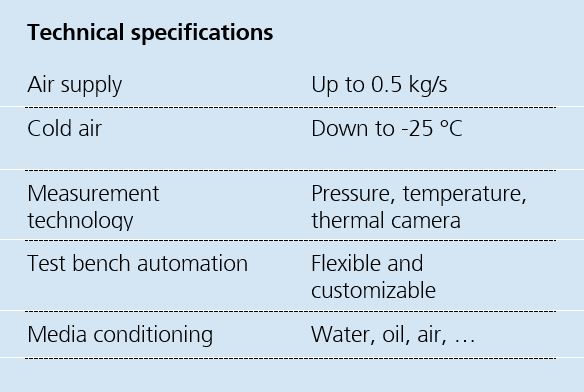

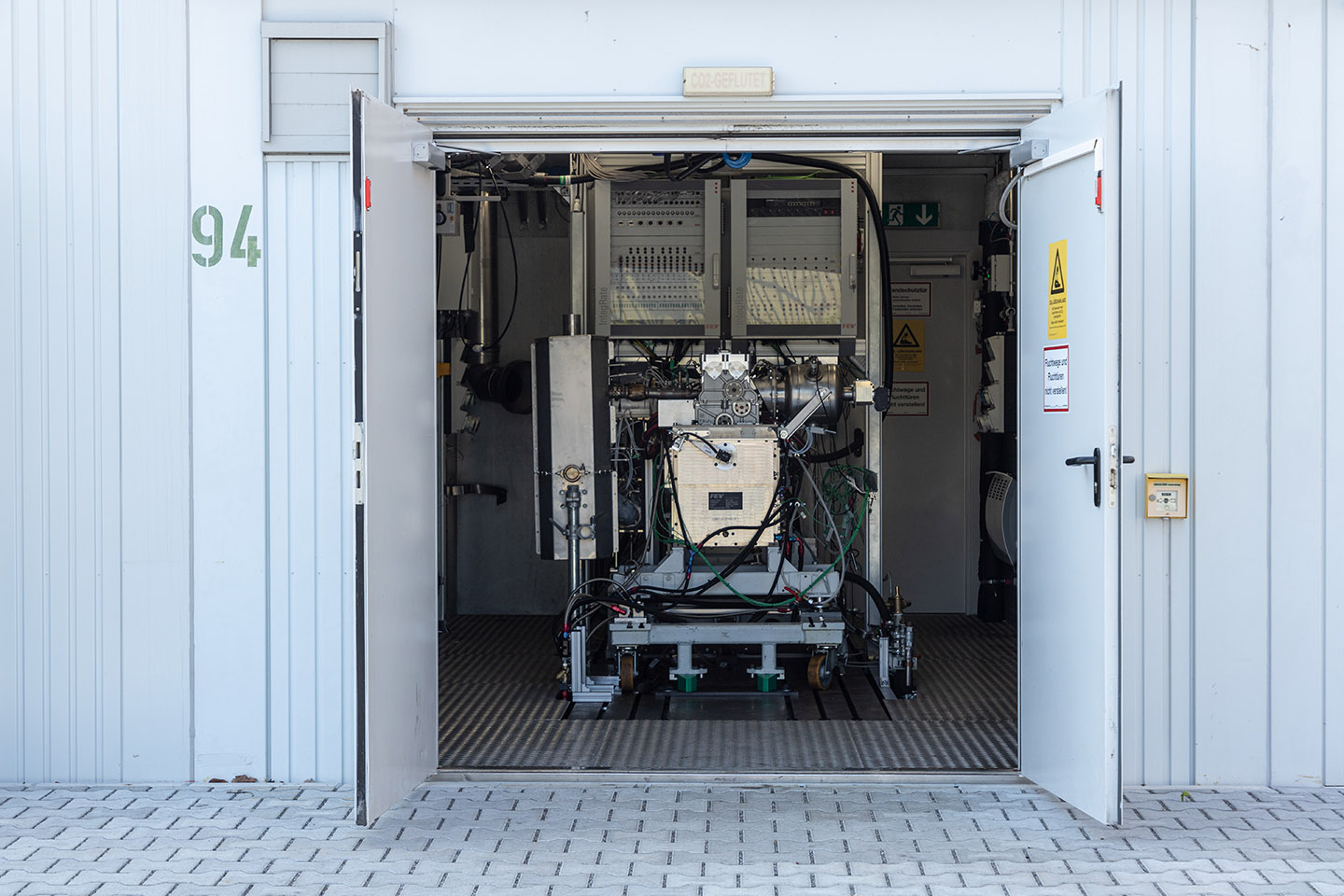

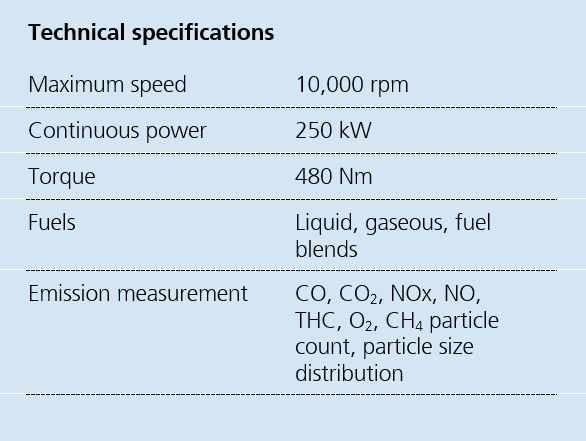

Multiple test stands are available in the testing and validation group to evaluate novel, CO2-neutral drive technologies and systems. These range from systems to acquire real-world driving data, and the testing of electric motors and hydrogen combustion engines, through to the highly flexible component and system test stands used, for example, to test the air supply components of fuel cell systems. If a new test stand is necessary, it is developed and constructed in collaboration with the design and simulation groups.

Connecting the test stands enables an efficient and holistic development process for modern drive technologies.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT