Drawing on our competence in the field of design, we carry out new developments of complex systems for our industrial and project partners. Our competence begins in the idea and concept phase. We develop drafts and create detailed designs and drawings with a view to production. In our commissioned projects we use CATIA V5 as a standard, in connection with a CAD data management system and additional, specialized software. Models are of course constructed top-down. To quickly visualize results, high-quality virtual product representations can be generated, or real models and functional prototypes can be created using Fraunhofer ICT’s 3D printers and technical workshop.

Design

Design competence

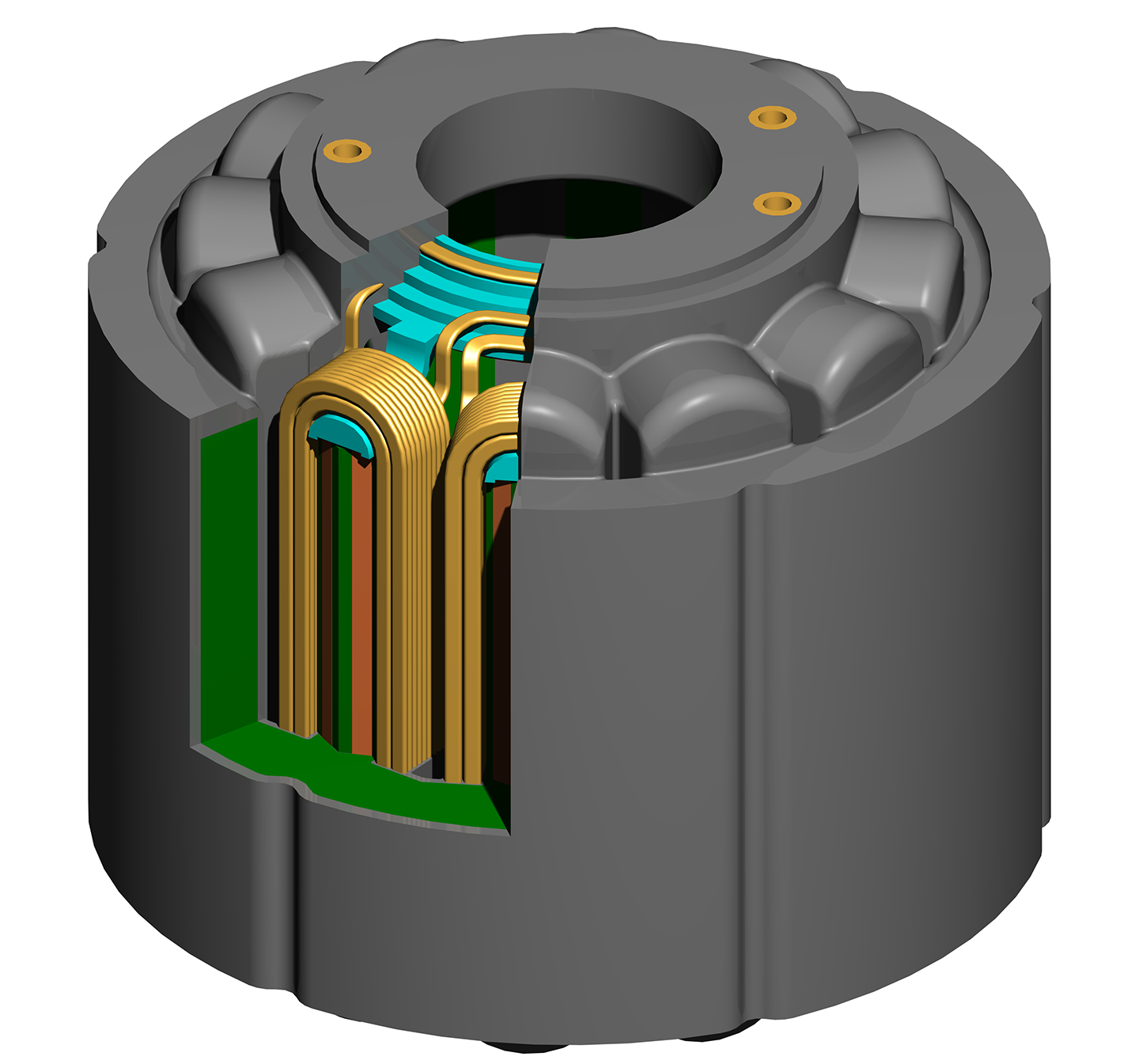

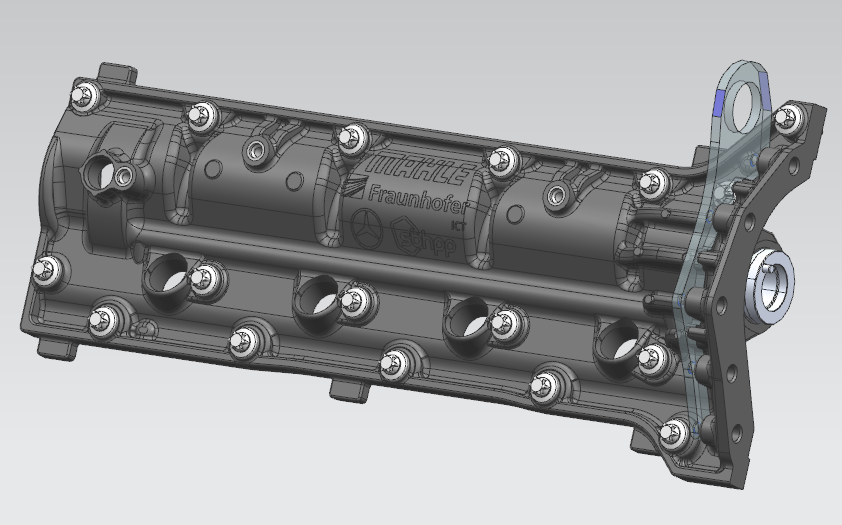

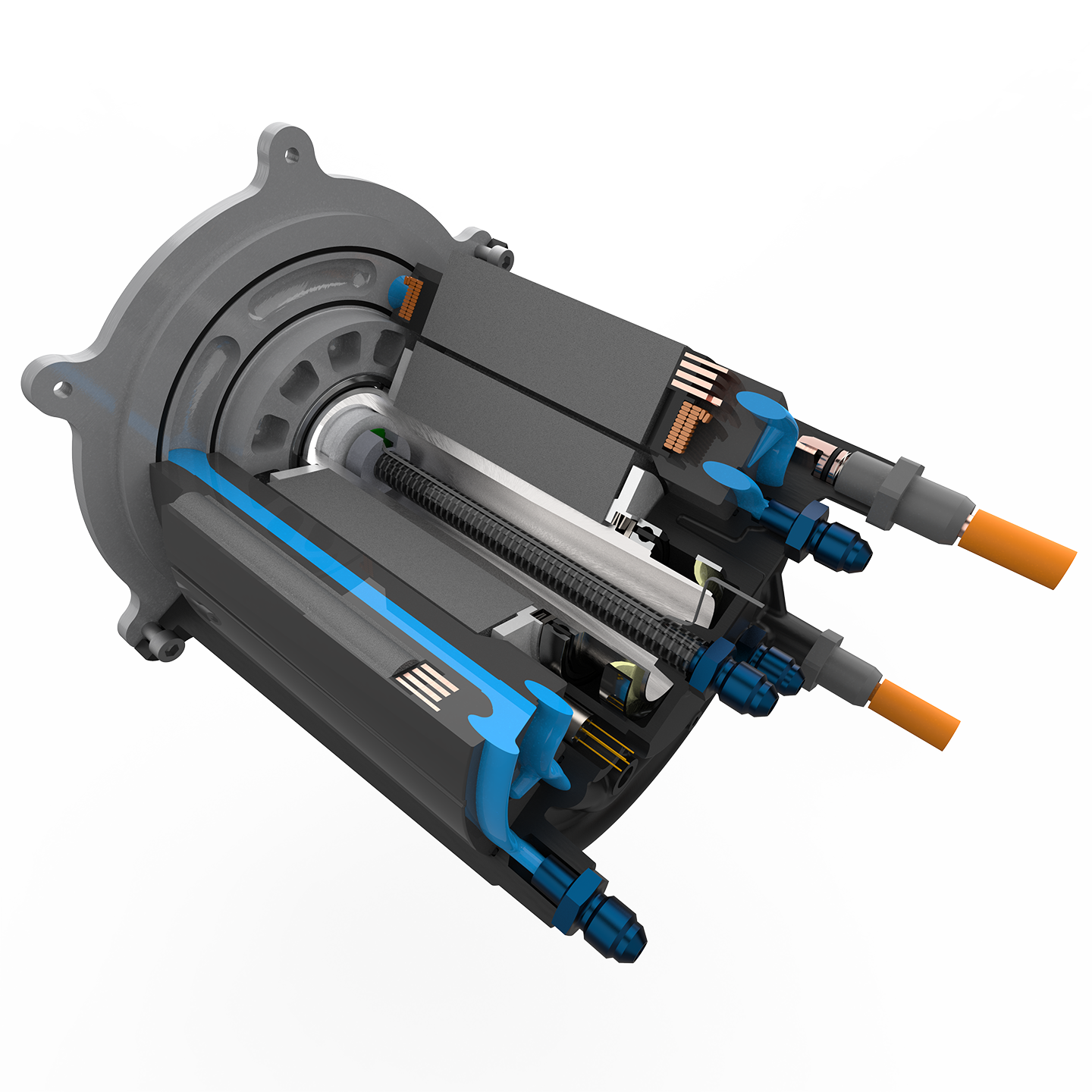

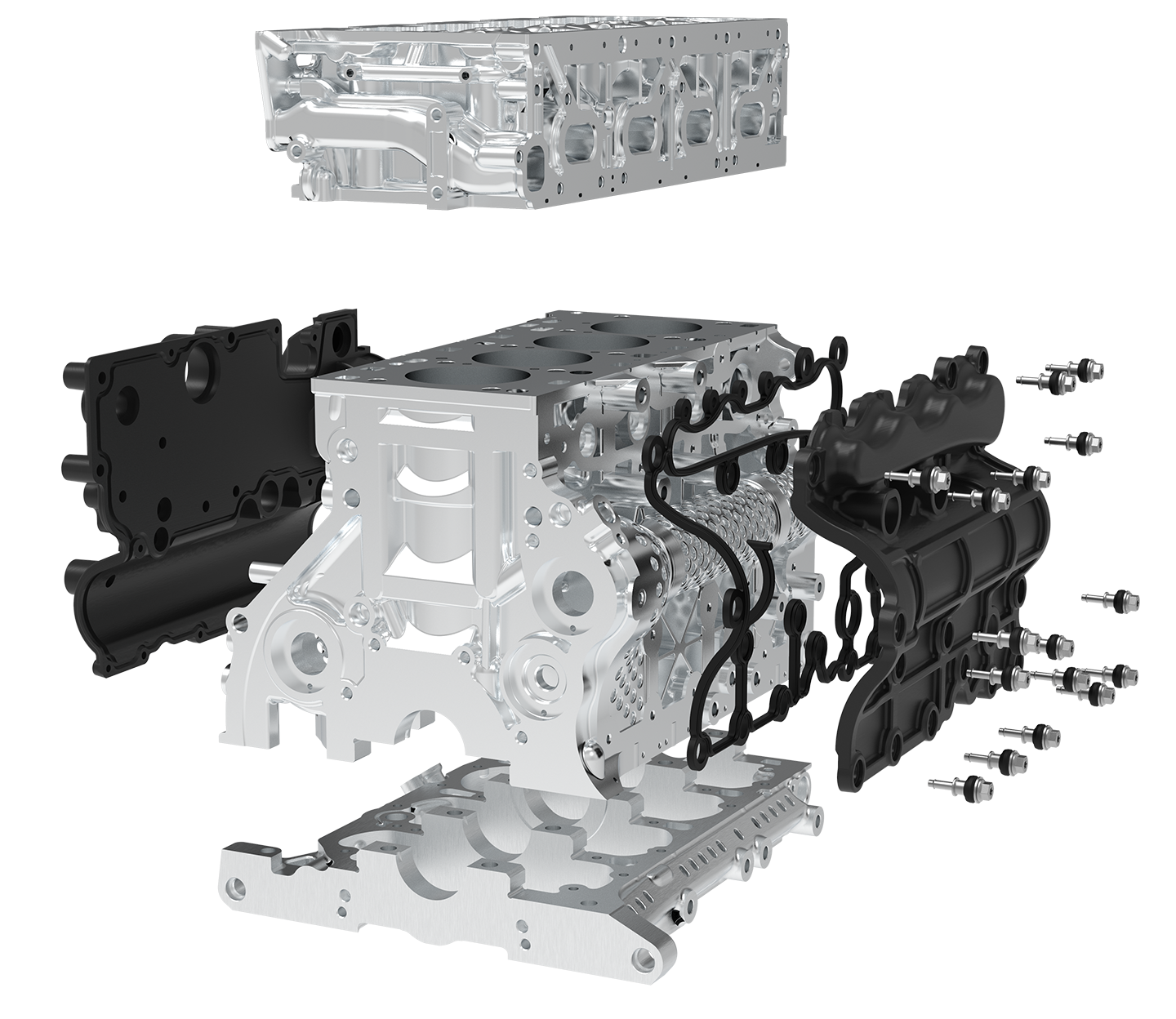

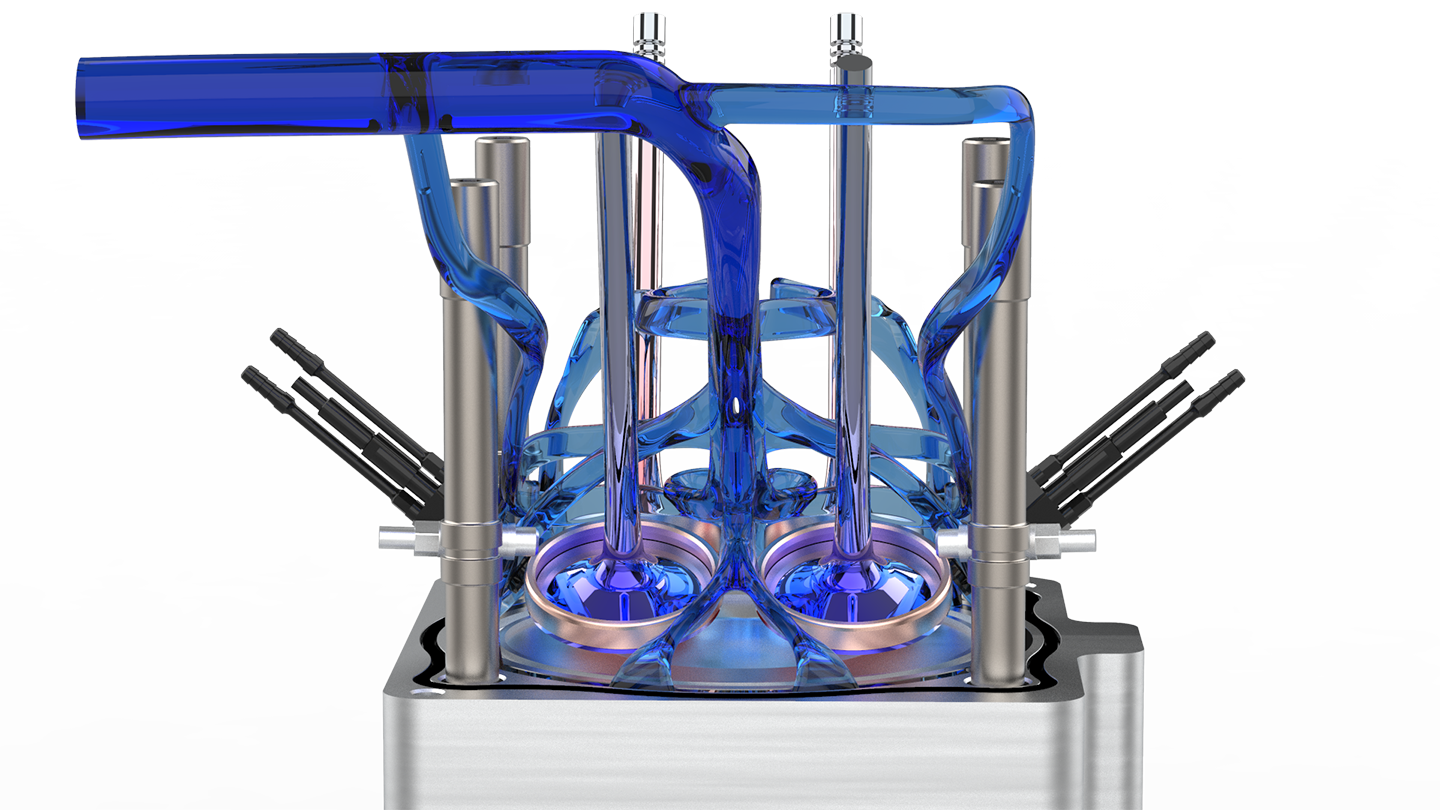

Drawing on our design competence, we carry out new developments of complex systems for our industrial and project partners. For example, we design and produce prototypes to validate new operating principles or layout concepts for traction batteries and electric engines, up to complete thermal energy converters such as combustion engines and turbines. Our competence begins in the idea and concept phase. We develop drafts and create detailed designs and drawings with a view to production. In our commissioned projects we use CATIA V5 as a standard, in connection with a CAD data management system and an extensive material database. To ensure the smoothest possible collaboration with our industrial partners, we apply a top-down construction method. This generates a clear and uniform component structure.

Clean sheet design (conception)

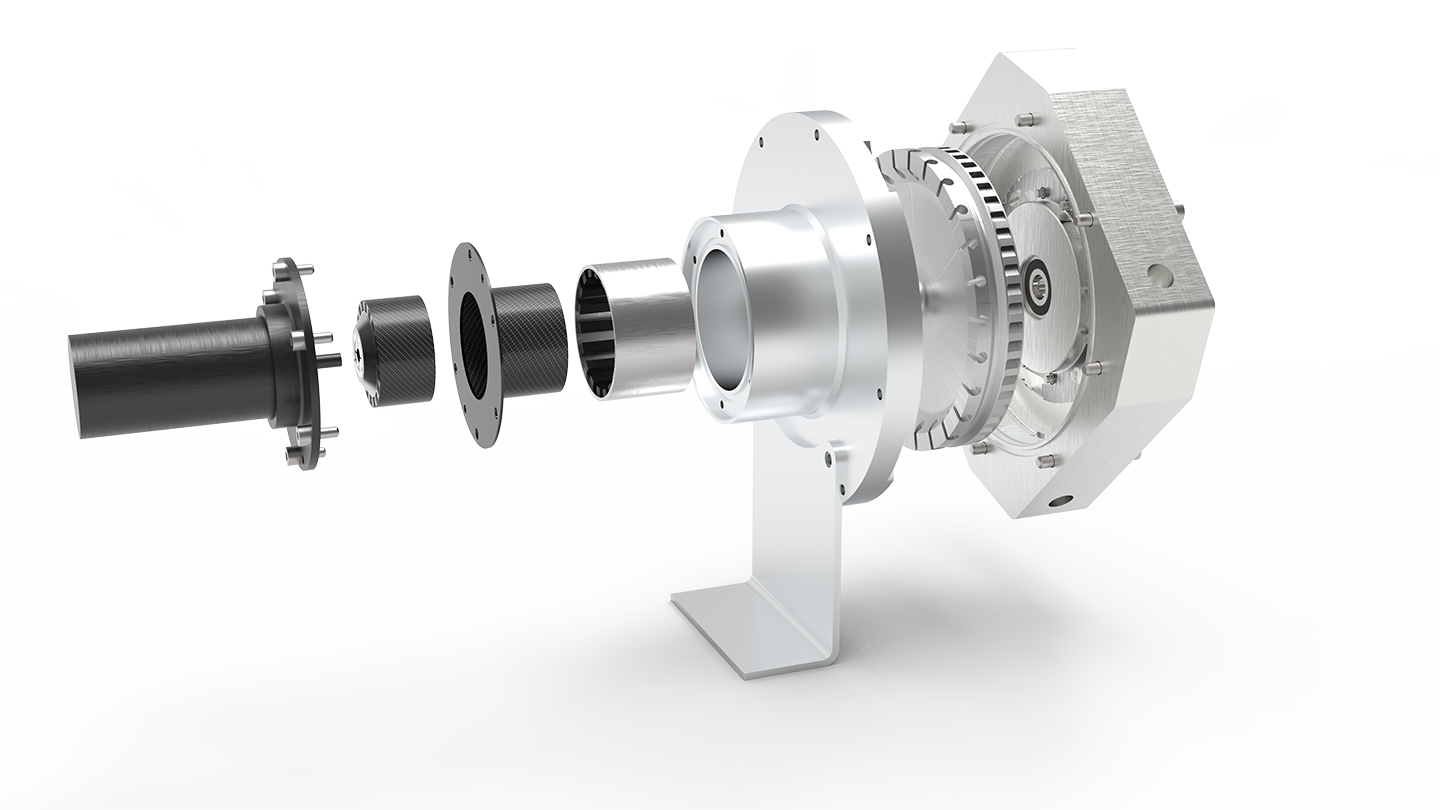

New manufacturing processes and materials also enable new areas of application. We have an extensive competence portfolio in the design of powertrain components and systems. Our expertise is based on numerous past projects, and on direct access to Fraunhofer ICT's other departments (including Environmental Engineering, Applied Electrochemistry and Polymer Engineering). The projects we have already completed range from the development of combustion processes, and the design of a single-cylinder engine, through to the packaging of a fuel cell system with a reformer and the design of an internal cooling system for an electric motor.

Redesign and optimization

Fiber-reinforced plastics in particular offer significant potential for lightweight construction and cost savings. However, a simple material substitution is never effective. We optimize existing designs to enable manufacturing with plastics and to fully exploit optimization potential. In close cooperation with our simulation group, we can make accurate predictions about the subsequent performance of the products and ensure a smooth construction process for the prototype.

New processes and materials

Through close cooperation with the Polymer Engineering Department, we have insight into the theoretical application of new processes and materials and also benefit from the comprehensive technology available in the pilot plant. In addition to high-volume processes, we also focus on additive manufacturing. In this field we design solutions to overcome the constraints of technology and take advantage of the unique opportunities for innovative components.

Packaging of components and entire systems

Cooperation with other research groups

Testing and validation

In close cooperation with the research group for testing and validation, prototypes can be tested for their ease-of-assembly and their functionality. Each step from design verification to complete prototype validation can be carried out on numerous different test benches.

Simulation

In-house simulation expertise enables efficient iteration loops and in-depth understanding of physical processes. Available simulations include flow, FEM, heat transfer and dynamics simulations.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT