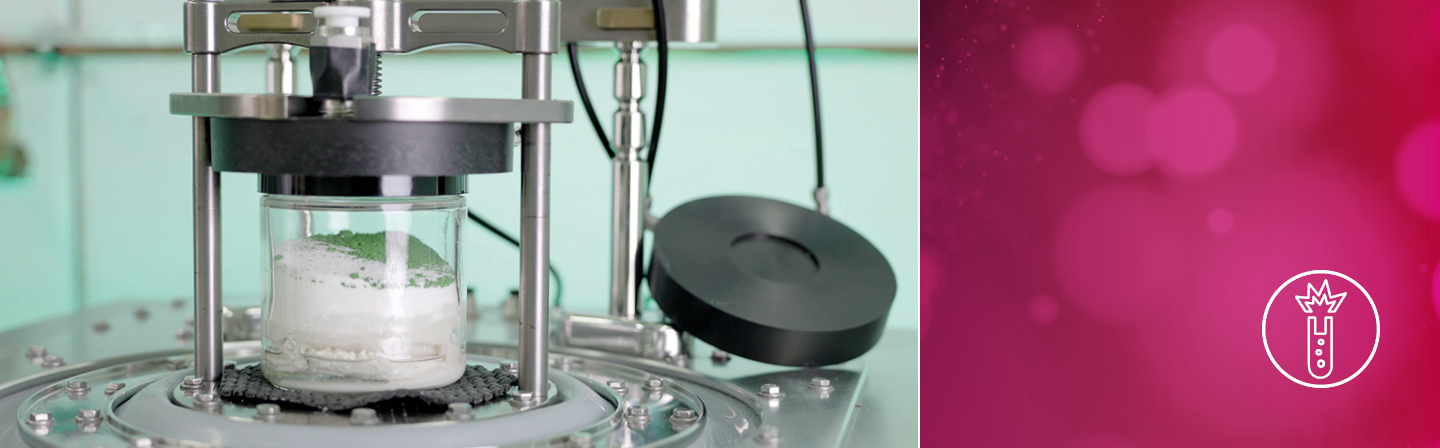

Development of propellants and explosives We deal with all aspects of the development, production and application of propellants and explosives, and can consequently manage the complexity of explosives technology along the entire competence chain. This includes molecular design, chemical synthesis, processing, shaping, and analytical characterization of high-energy materials and derived formulations for rocket propellants, gun propellants and explosives, which we develop and evaluate in the form of prototypes, small batches and demonstrators. In line with our founding motivation as the “Institute for Propellants and Explosives” in 1959, this expertise is primarily defense-oriented, and serves to maintain the analysis and evaluation capability of the German army. This advisory expertise is secured by basic funding from the Federal Ministry of Defense (BMVg). Synthesis, processing and manufacturing methods Modern propellant and explosive formulations are highly filled plastics. Their burning behavior, detonation behavior, sensitivity and mechanical properties are strongly dependent on the particle and crystal properties of the fillers. The optimum design of the fillers (explosives and additives) is therefore the key to achieving subsequent product properties. For this purpose, we develop and test comminution, crystallization, prilling and coating processes. New substances must be available on a kg scale in order to test their performance properties in formulations. Our reaction technology therefore forms the bridge from laboratory synthesis to robust, upscalable production techniques, in order to provide sufficient sample material for further steps, including industrial developments. For the various product groups of gun propellants, rocket propellants, gas generators, explosives and pyrotechnics, special processing techniques tailored to the respective explosives are applied and developed. These include processes for mixing and homogenizing, pressing, extruding, injection molding or foaming. Performance measurement and characterization The chemical synthesis of new explosives, whose properties are not yet known or are poorly understood, is challenging and requires special methods to measure and characterize performance. Our basic methods include the measurement of friction and impact sensitivity, thermal behavior, stability, compatibility, purity, crystal structure, mechanical behavior and the determination of other chemical and physical parameters. A particular area of expertise is thermodynamic power calculations with our own Fraunhofer ICT code. We have the secure infrastructure and extensive measurement technology needed to characterize the burning, deflagration and detonation behavior of propellants and explosives. This includes technology developed within the institute. Modeling and simulation We accompany experimental investigations with modeling and simulation calculations. These include quantum mechanical and molecular dynamic simulations, the modeling of burnup behavior using kinetic models, and calculation of the expected stability, aging and performance. Stability and aging behavior We have extensive experience and experimental methods to determine the kinetic parameters of energetic materials. This allows us to measure thermal and mechanical stability, aging behavior including long-term predictions, and compatibility in formulations. We are proficient in handling all types of energetic materials, including highly sensitive materials such as nitroglycerin or TATP. Explosives detection Our knowledge of the production and properties of explosives makes us particularly well qualified to engage intensively in national and European security research. One focus of our work is the remote and trace detection of explosives, including so-called home-made explosives (HMEs) and improvised explosive devices (IEDs). We determine the properties of HMEs and IEDs, and research methods to detect them. Because we can safely assess terrorist explosives and fabricate them for testing purposes, we operate a test center for aviation security detection equipment on behalf of the German Federal Police, and support them with security issues relating to HMEs. In our test center for detection systems, we offer the manufacturers of airport scanners and detection devices the opportunity to carry out tests with real explosives and reference substances, in order to evaluate and optimize their systems. In cooperation with the German Federal Police, the institute also tests and certifies such systems for use in European airports. Furthermore, we draw on our explosives expertise to solve current challenges in technical safety, for example hydrogen safety, explosion protection, fire protection and the control of thermal runaway reactions in chemical synthesis processes and energy storage systems. |

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT