Research project Clean Sky

Clean Sky 2-Programme

The Clean Sky Programme aims to develop cleaner air transport technologies. That means integrating, demonstrating and validating technologies capable of reducing CO2, NOx and noise emissions.

Clean Sky aims to develop cleaner air transport technologies for earliest possible deployment. That means integrating, demonstrating and validating technologies capable of reducing CO2, NOx and noise emissions by 20 to 30% compared to ‘state-of-the-art’ aircraft entering into service as from 2014. Besides improving the environmental impact of aeronautical technologies, including those related to small aviation, the objective of Clean Sky 2 is also to develop a strong and globally competitive aeronautical industry and supply chain in Europe.

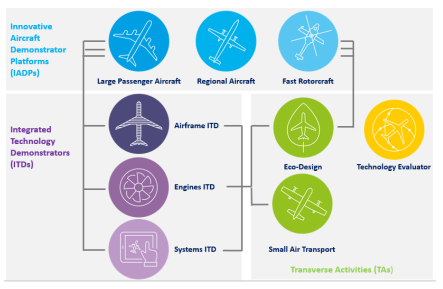

Clean Sky’s programme structure is outlined in the diagram below. It is composed of the three IADPs – Innovative Aircraft Demonstration Platforms – (Large Passenger Aircraft, Regional Aircraft and Fast Rotorcraft), three ITDs – Integrated Technology Demonstrators (Airframe, Engines and Systems) as well as three TAs – Transverse Activities (Small Air Transport, Eco-Design and Technology Evaluator). The three Transverse Activities have relevance to several ITDs and/or IADPs and require coordination or management across the ITDs and/or IADPs.

Duration

03/2014 - 03/2024

Funding

Co-funded by the European Union

Clean Sky 2 Eco-Design Transversal Activity

Eco-Design TA will provide an assessment of the innovative ecoDESIGN technologies currently undertaken in Clean Sky 2. Focus of the assessment is on the ecoDESIGN flagship demonstrators representing big essential parts of the aircraft and the eco-efficient production plants.

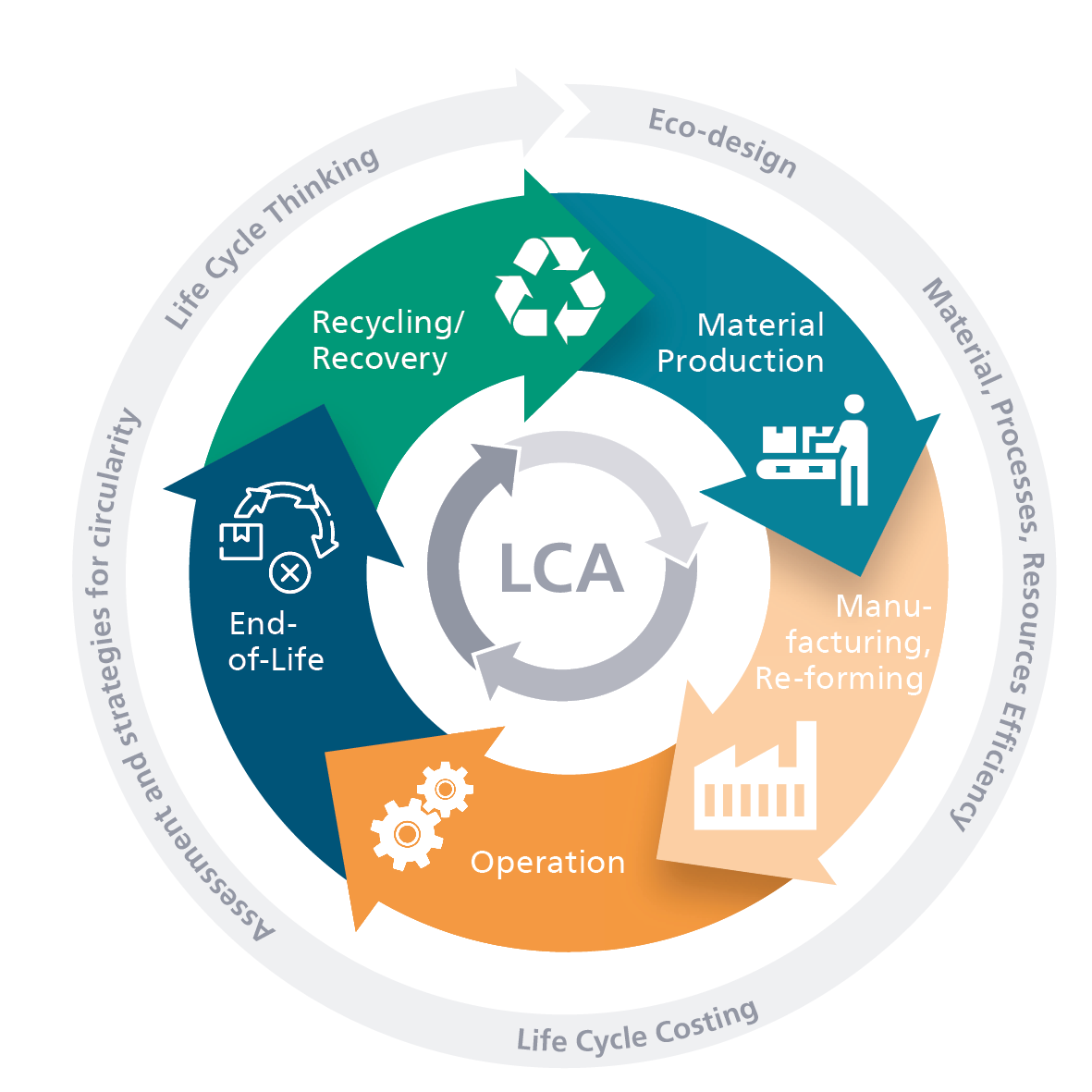

The Eco-Design Transverse Activity (TA) is the part of the Clean Sky programme that focuses on the overall ‘cradle to cradle’ approach to design, manufacturing, maintenance and disposal (including recycling), examining the basic elements of materials, processes and resources, and advancing that science in areas of performance across the entire lifespan of those elements. All of this helps to ensure a heightened level of eco-compliance across other Clean Sky Integrated Technology Demonstrators (ITDs) and Innovative Aircraft Demonstrator Platforms (IADPs).

Eco-Design takes the full cycle from idea to end-of-life disposal of the aeronautical industry's products and services and revisits every step as well as the ‘whole life cycle’ in terms of impact on the Earth’s resources, energy consumption, waste and elimination of hazards and harmful elements. This often necessitates going back to basic assumptions relating to materials, processes and resources in order to maximise ecological readiness for tomorrow's air transport system and its footprint in environmental and societal terms.

Eco-Design's remit is to step into the processes of other programmes, when appropriate, if relevant new and environmentally-friendly materials or processes become available. It's a continuous and evolving process – but one which adds quality to the evolving demonstrators across all programmes, keeping them at the forefront of sustainable technological accomplishment in aeronautics.

In order to prepare for the most complete and efficient aeronautical ecosystems of the future, the Eco-Design TA will provide an assessment of the innovative technologies currently undertaken. The principles of an extended aeronautical database and novel life-cycle assessment (LCA) methodologies will be developed with a sustainable vision to help quantify the environmental benefits of the most promising technologies and orient the research in the Eco-Design themes.

Duration

03/2016 - 03/2024

Funding

Co-funded by the European Union

Clean Sky 2 Airframe ITD - Eco-Design

Sky 2’s Airframe Integrated Technology Demonstrator (ITD) delivers decisive technology innovations for all Aircraft vehicles.

The focus in Airframe ITD - Eco-Design is developing technologies to reduce the carbon footprint. Fraunhofer is leading Eco-Design in Airframe ITD and Fraunhofer ICT developed material concepts for Hybrid seating structures.

The Hybrid Seating Structure Demonstrator is based on one hand side on CS1 results for the seating cushion demonstrator and on the other hand side on new manufacturing technologies.

Several eco-relevant improvements are implemented:

- Elimination of hazardous flame retardants to reduce the Ground Pollution Potential (GPP)

- Weight reduction compared to SoA seating bank

- Mono-material concept for the whole seating bank for affordable recycling concepts

- High Re-use and Recycling Quota (RRQ) due to solvolysis concept

- Wet compression moulding (WCM) for serial production instead of High-Pressure Resin Transfer Moulding (HPRTM)

- Sheet moulding compound (SMC) for visible parts

- Re-Use of recovered fibre potential due to SMC and WCM technology

Duration

01/2015 - 03/2024

Funding

Co-funded by the European Union

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT