Sumitomo Bakelite Co., Ltd. and the Fraunhofer Institute for Chemical Technology ICT will collaborate in the development of composite materials for innovative functional and structural engine parts

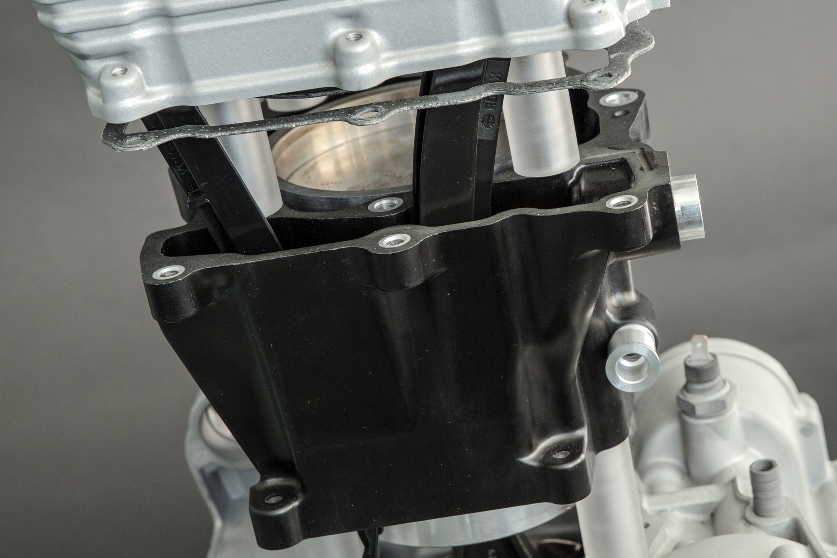

At the Hannover trade fair in 2015, the two partners presented a lightweight single-cylinder research engine with a cylinder housing made of fi ber composite material produced by Sumitomo Bakelite Co., Ltd.

The advantages of the phenolic-based fi ber composite material are a potential weight reduction of about 20% compared to aluminum, and a potential cost reduction in large series production through the use of injection molding. In addition, these engines can offer improved acoustic behavior due to the superior damping properties of the phenolic resin compared to metal alloys, and better thermal properties due to a lower thermal conductivity. These advantages were documented during fi red engine tests on the engine test stand at Fraunhofer, using the 650 ccm single-cylinder engine displayed at the Hannover trade fair.

According to the project leader at Fraunhofer, Lars Fredrik Berg, the technology has further

potential: „Besides cylinder housings and engine blocks, fi ber composites such as Sumitomo Bakelite Co., Ltd.’s high-performance composite materials can be used in many other components in the drive train, to reduce weight and improve overall performance.“ The materials are also opening up new possibilities in component design: „We are just starting to explore a range of new benefi ts and options which would not be possible with aluminum,“ Berg explains.

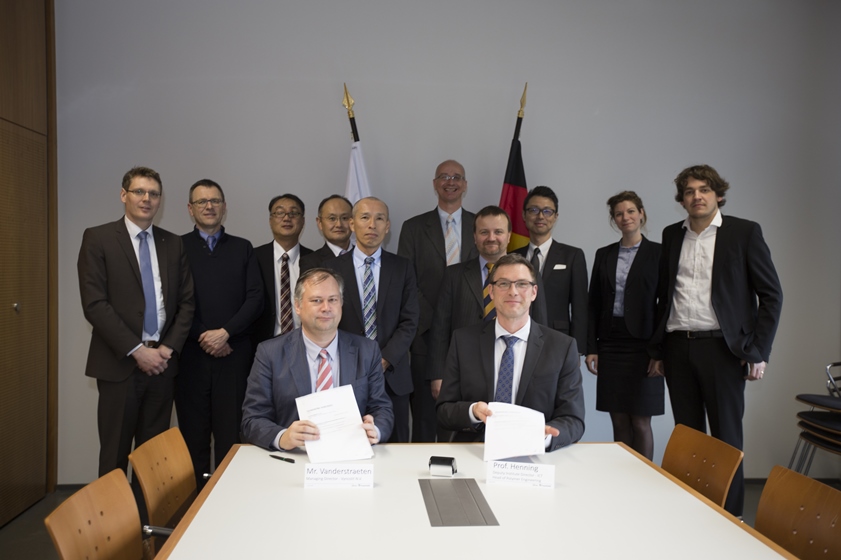

„Sumitomo Bakelite Co., Ltd. materials offer signifi cant potential for application in and outside the drive train,“ adds Pieter Vanderstraeten, CEO of Vyncolit, the European production company for the composite molding compounds of Sumitomo Bakelite, Co., Ltd. in Belgium. “The cooperation with Fraunhofer will accelerate the automotive industry’s adoption of these materials for innovative functional and structural engine parts. Sumitomo Bakelite Co., Ltd. is launching the sbDRIVE initiative to the automotive industry for the full development of lightweight solutions at acceptable cost in the automotive powertrain. It includes concept work, design iterations, composite material development and production techniques, prototyping, and validation testing up to industrialization for large-series production. In all of these fi elds, an intensive cooperation with Fraunhofer has been agreed.

Over the coming years, the two partners will work together „to make drive trains lighter, better and more compact, and of course to integrate Sumitomo Bakelite Co., Ltd. materials into a variety of new applications,“ Vanderstraeten explains.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT