A group of European partners today announce the selection of the HYGHER (“HYdroGen High-pressure supply chain for innovative and cost Efficient distRibution) project in the competitive call “Demonstration of high-pressure (500-700 bar) supply chain” organised by the Clean Hydrogen Partnership.

This new project will demonstrate innovative technologies for transporting hydrogen at high pressure from production sites to refuelling stations – on a scale and at pressure levels that are unprecedented in today’s hydrogen mobility market. With a grant of 5 million euros awarded by the Clean Hydrogen Partnership, the project will focus on real-life demonstration of innovative components and their optimal integration across the hydrogen distribution value chain. The project has started in January 2024, and will run for 36 months.

From concept to reality with joint efforts

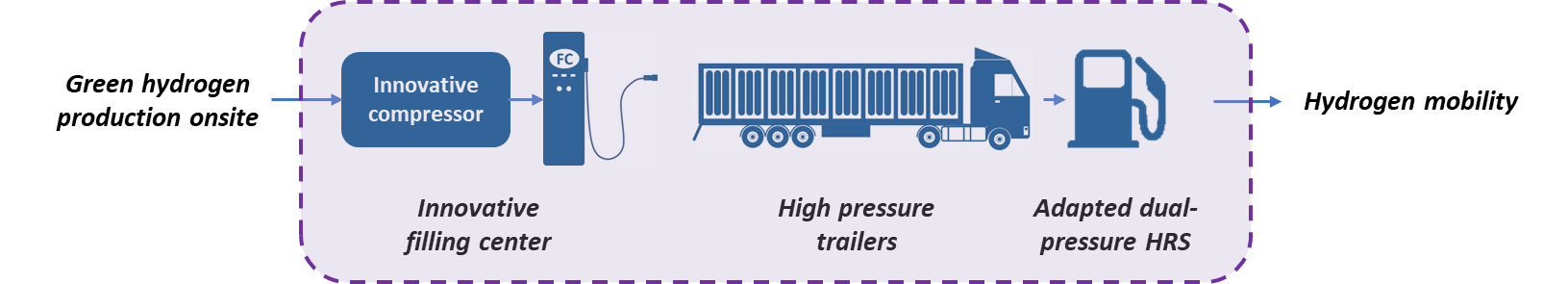

HYGHER is run by a European consortium of leading research institutions and innovative SMEs. The European Institute for Energy Research (EIFER, Germany) coordinates the project and will assess the economic performance of the demonstrated value chain. Two innovative SMEs will manufacture the main sub-components: EIFHYTEC, a French start-up, will manufacture a thermo-chemical compressor to compress hydrogen at the production site. RECOMA, an Italian trailers integrator, will produce two high-pressure trailers featuring novel cascading concepts for optimised filling and unloading. HYPE, the pioneering green hydrogen mobility platform launched in Paris in 2015, will operate the entire HYGHER high-pressure distribution value chain, which includes:

- The new innovative high-pressure filling centre, which integrates the EIFHYTEC compressor and is connected to one of HYPE’s own green hydrogen production units in the Paris area;

- The distribution of compressed hydrogen to HYPE’s hydrogen refuelling station (HRS) network in the greater Paris area (Île-de-France) using the project’s first-of-its-kind high-pressure RECOMA trailers.

The Fraunhofer Institute for Chemical Technology (Germany) will develop a dedicated safety approach including research and improvement for regulations, codes and standards as well as the performance of risk analysis. The University of Ljubljana (Slovenia) will ensure early integration of circularity aspects to maximise the sustainability of the value chain.

From the start, technical and market conditions for future upscale will be investigated and replications prepared. To that end, the consortium will be supported by German technology transfer centre Steinbeis Europa Zentrum, which will also raise awareness about the potential and benefits of the HYGHER solution, to accelerate market uptake.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT