Bioeconomy (BioEco)

Our society needs sustainable raw material alternatives to achieve a climate-neutral bioeconomy and to replace petroleum with renewable resources in products. Biomass is the sole source of renewable raw materials. The research group for bioeconomy within Fraunhofer ICT’s Environmental Engineering Department is working to develop scientifically sound and environmentally friendly technologies based on green chemistry and engineering. The aim is to obtain competitive materials and products from wood and other biomass while minimizing waste. Research and development focus on biorefinery, sustainable chemical conversion processes, biobased materials, and plastics.

We are convinced that bioeconomy is a crucial part of a sustainable and future-oriented economy. For this reason, we actively advocate for the promotion and advancement of sustainable processes and renewable resources. In collaboration with our partners and customers, we develop customized solutions tailored to specific needs. Our goal is to create innovative products based on renewable resources, providing an environmentally friendly alternative to traditional products. Through our work we make a positive contribution to resource conservation and climate protection. We are proud to be part of a movement that is committed to a sustainable and future-oriented economy.

Biorefinery

Rising raw material prices and dwindling reserves of fossil resources have led to significant interest in sustainable processes and the use of renewable resources. The research efforts of the bioeconomy group therefore include the extraction and purification of chemically interesting components from renewable resources, such as the breakdown/fracturing of lignocellulose, insect biorefinery, sugar-starch biorefinery, plant oil biorefinery, the utilization of biogas and the fractionation of manure from animal farming.

Sustainable chemical conversion processes

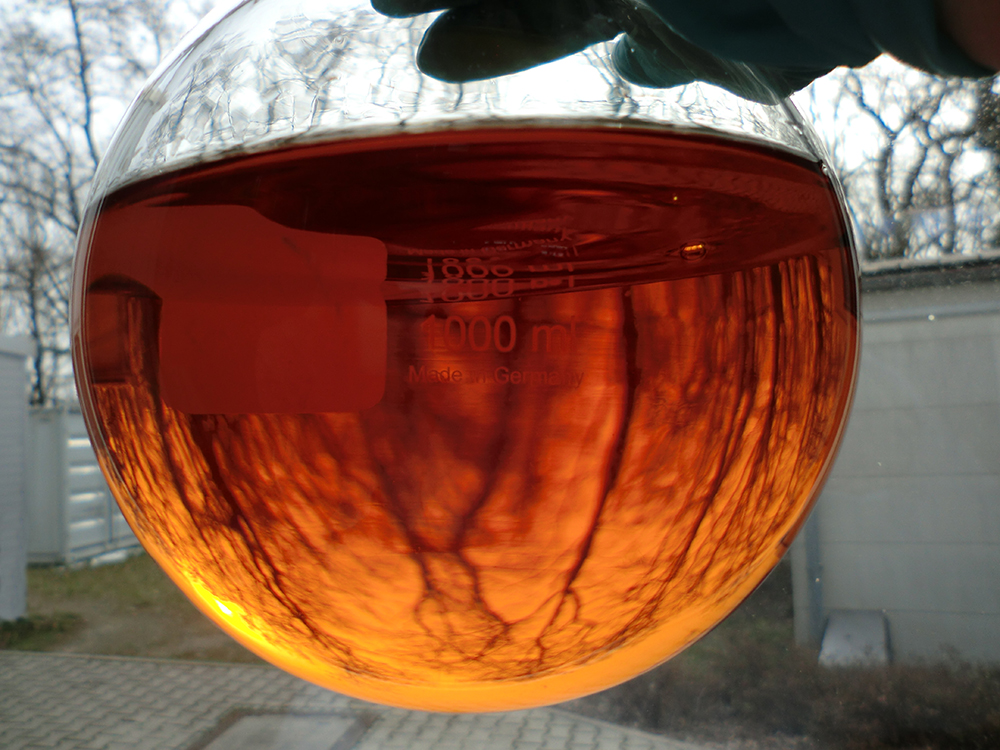

Biobased raw materials are rarely usable in their directly obtained form in a biobased chemical product. For this reason, biobased intermediates (e.g. cellulose, lignin, various fatty acids, etc.) are chemically transformed or functionalized to achieve product-specific properties. This is accomplished using various methods such as oxidation (e.g. TEMPO oxidation, lignin condensation), hydrogenation, high-pressure reactions (e.g. sugar to HMF), heterogeneous catalysis for the production of sustainable products (e.g. CCU), and base-catalyzed reactions.

Biobased materials and plastics

Biobased materials and plastics are produced from renewable resources and are therefore an environmentally friendly alternative to conventional plastics produced from non-renewable fossil resources. They also offer potential for new applications and innovations in various industries, from packaging and construction to electronics. Some examples of biobased materials and plastics include:

- Tannin-based NIPU (e.g. adhesives)

- Thermoplastic lignin derivatives in bitumen binders

- Phenolic building blocks from lignin

- Biobased polymers for adhesives, coatings, and additives

- Micro- and nanofibrillated cellulose

- Alcohols from CO2

Tannin-based NIPU is adhesives made from tannin - a natural phenol - and polyurethane. They are used in the wood industry as an environmentally friendlier alternative to formaldehyde-based adhesives.

Thermoplastic lignin derivatives are made from lignin - a natural polymer - and can be used as bitumen binders in the road construction industry to substitute oil-based bitumen and extend the lifespan of road surfaces.

Phenolic building blocks from technical lignin can be used as binders in the production of particleboard and MDF as an environmentally friendly alternative to formaldehyde-based binders.

Biobased polymers for adhesives, coatings, and additives can be made from various renewable resources like corn starch, cellulose, or plant oils, providing an eco-friendly alternative to conventional petrochemical polymers.

Micro- and nanofibrillated cellulose, due to their high specific surface area, can achieve high strength, and find application in various fields such as packaging, paper, textiles, and biocomposites. They can be produced from plant-based raw materials like wood.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT