Our research focus is on improving functional safety and increasing the efficiency in order to enhance the overall performance of electric vehicles and extending the range and the overall useability. Our research group in the area of electromobility covers various topics, for example the development of elecric drive units incorporating compact electric motors with high continues power output and corresponding light weight transmission systems.

Electromobility

Lightweight and oil-free gear box concept – directly cooled electric motor – lightweight traction battery system

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyLearn more about our innovative solutions for electromobility!

- Lightweight gearbox housing for an existing battery electric vehicle: 100% oil-free operation, production of low-loss gears by rolling processes, carbon coating of the gears to reduce friction, lightweight carbon fiber reinforced composite (CFRP). By combining CFRP, foam and elastomers, the weight could be reduced by more than 25% while offering an extreme stiffness and an optimized acoustic behavior.

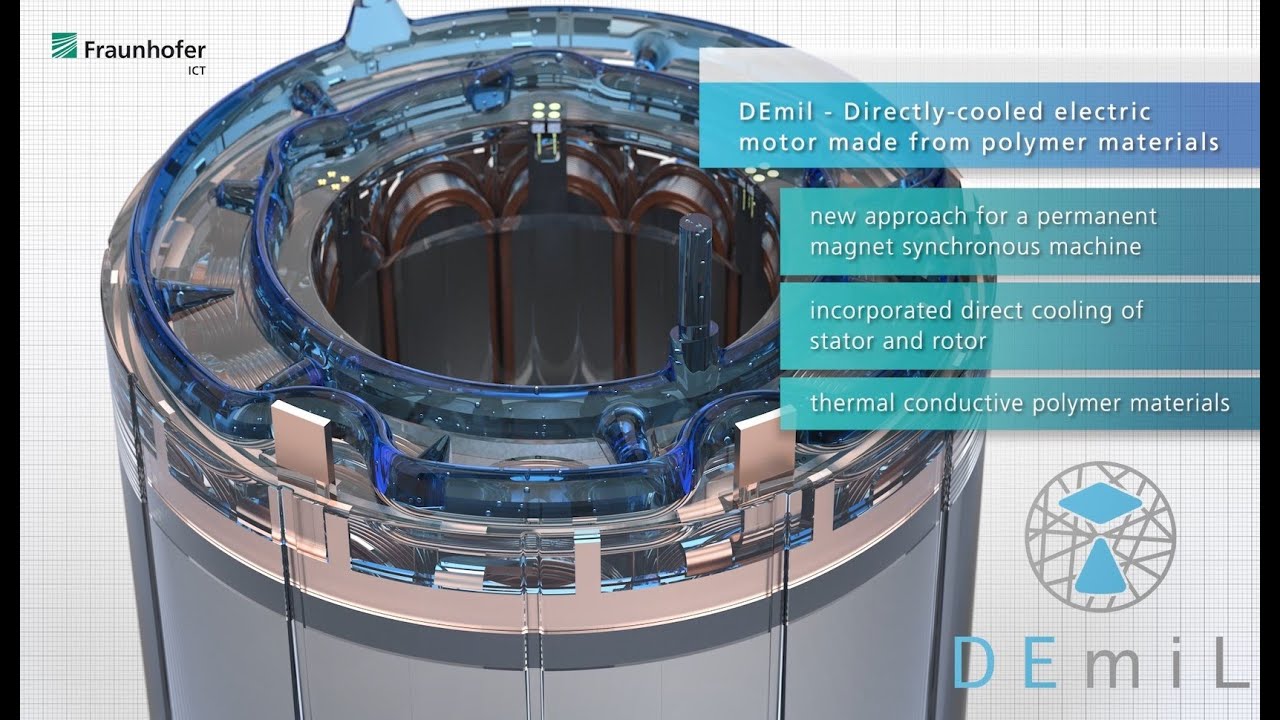

- Directly cooled electric motor: cooling concept of a permanent magnet synchronous machine. This cooling concept significantly increases the continuous power density of the motor, while at the same time enabling a highly compact and lightweight design.

- Lightweight traction battery system: The high voltage battery offers a great potential for weight reduction by applying a lightweight design. Due to the high power, challenges arise for the cooling system of traction batteries. We have developed a base plate with integrated cooling as a flat sandwich component in a pressure-controlled resin transfer molding process, taking all necessary properties such as thermal conductivity, flame retardancy and electromagnetic shielding into account.

In the area of high voltage traction batteries we focus on applying an innovative design approach and the use of light weight materials to reduce weight and to enable functional integration of elements such as high performance thermal management systems for performant thermal conditioning of the battery systems.

For further information please contact us or inform yourself about our current research projects.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT