Trade fair / October 08, 2025 - October 15, 2025

K 2025

Fraunhofer ICT was part of the joint booth of the Fraunhofer Gesellschaft on the Science Campus in Hall 7, Level 0, booth C05 at K 2025.

Fraunhofer ICT was part of the joint booth of the Fraunhofer Gesellschaft on the Science Campus in Hall 7, Level 0, booth C05 at K 2025.

Düsseldorf Fair: Hall 7, Level 0, Booth C05

Am Staad (Stockumer Höfe), D-40474 Düsseldorf

October 08, 2025 - October 15, 2025

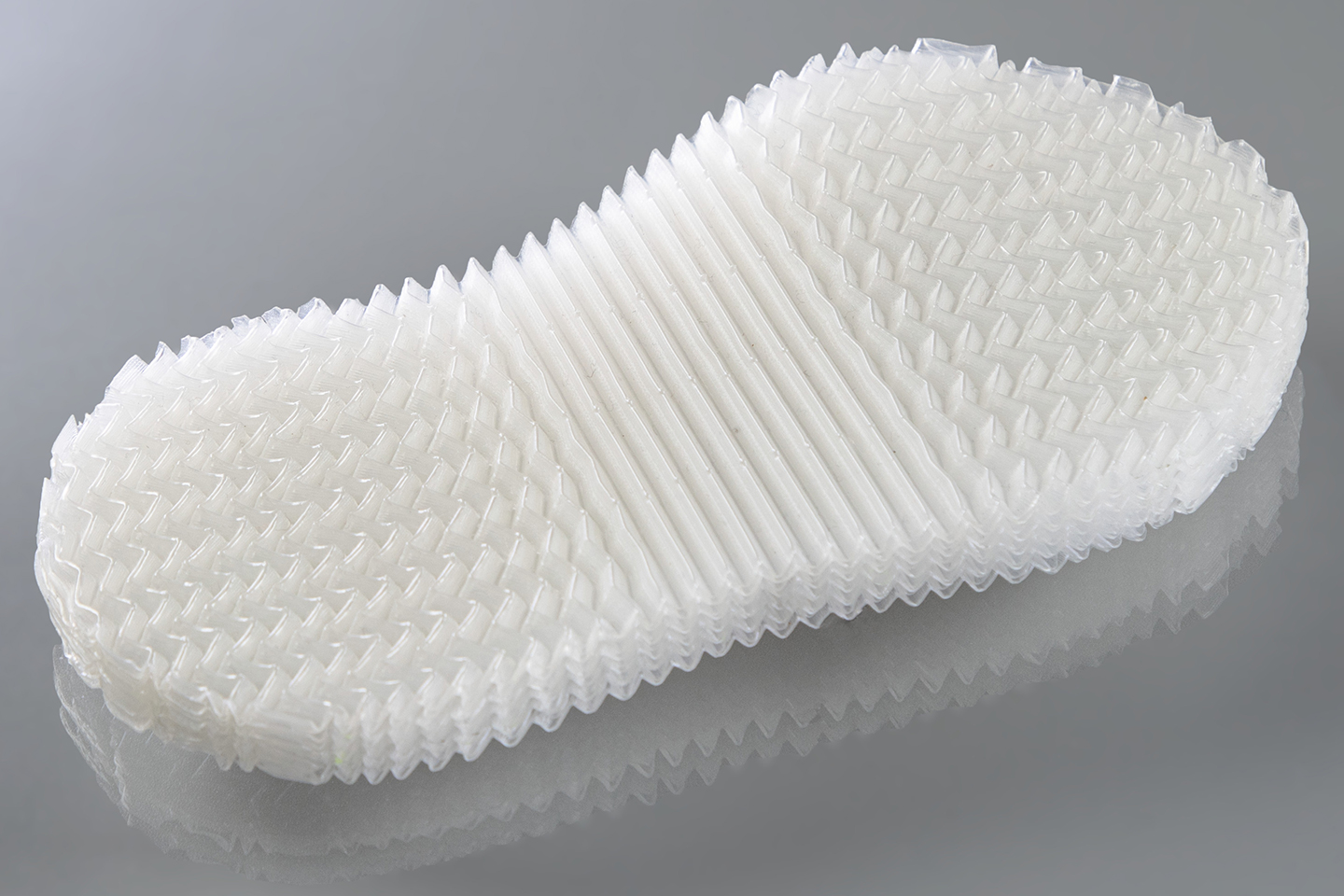

The demonstrator is based on a lightweight construction concept that is based entirely on a single material - PET. By combining joining technologies suitable for large-scale production and functional surface modifications, recyclable and recyclate-based plastics are used efficiently. Using sandwich technology, self-reinforcing PET fibers are embedded in a PET matrix and then bonded with PET structural foams to form sandwich structures - completely adhesive-free. This joining principle minimizes material heterogeneity and thus facilitates material recycling.

Different morphologies are integrated using coordinated processes that combine thermoforming and injection molding. As a result, complex, multifunctional components with optimized lightweight construction potential and high production and recycling efficiency can be realized.

The advantage for users: a completely closed material cycle that enables sustainable large-scale production with a reduced environmental footprint - without compromising on functionality and component performance.

Circular design using a bio-based mono-material approach: All components of the helmet (shell, foam, straps and add-on parts) are made from the same plastic, resulting in a ‘mono-material design’. This means that the helmet can be mechanically recycled at the end of its life cycle without disassembly and returned to the same application. In addition, the entire helmet is made from a bio-based plastic (polylactide). Sustainable materials are finding their way into the sports industry - now also for cycling helmets. A new helmet made entirely from bio-based polylactide reduces CO2 by two thirds compared to con-ventional models, without compromising on protection. Its construction from a single material also enables material recycling, which was not possible with the previous composite material.

The shell is made from either thermoformed PLA film or self-reinforced PLA, while the core is made from expanded PLA (EPLA) as a sustainable alternative to EPS. The straps, clips and size adjustment system are also made of PLA.

The protective effect of the helmet is based on the compression of the EPLA foam core, whereby the impact is distributed evenly across the helmet by the PLA shell. EPLA is a bio-based alternative to EPS (brand name BASF: polystyrene) with comparable properties. It is also compatible with existing production systems and enables the production of components with densities between 30 kg/m³ and 150 kg/m³ in established series processes. This means that an equally safe but more environ-mentally friendly helmet can be produced.

The materials and manufacturing processes developed for the helmet can be transferred to other products, such as surfboards, backpacks, protectors or fascia rolls.

Old plastic becomes new washing machine parts: In the EU project Plast2bCleaned, 23 front covers for door frames were produced with 30% recycled ABS content – successfully tested mechanically and for REACH-compliance.

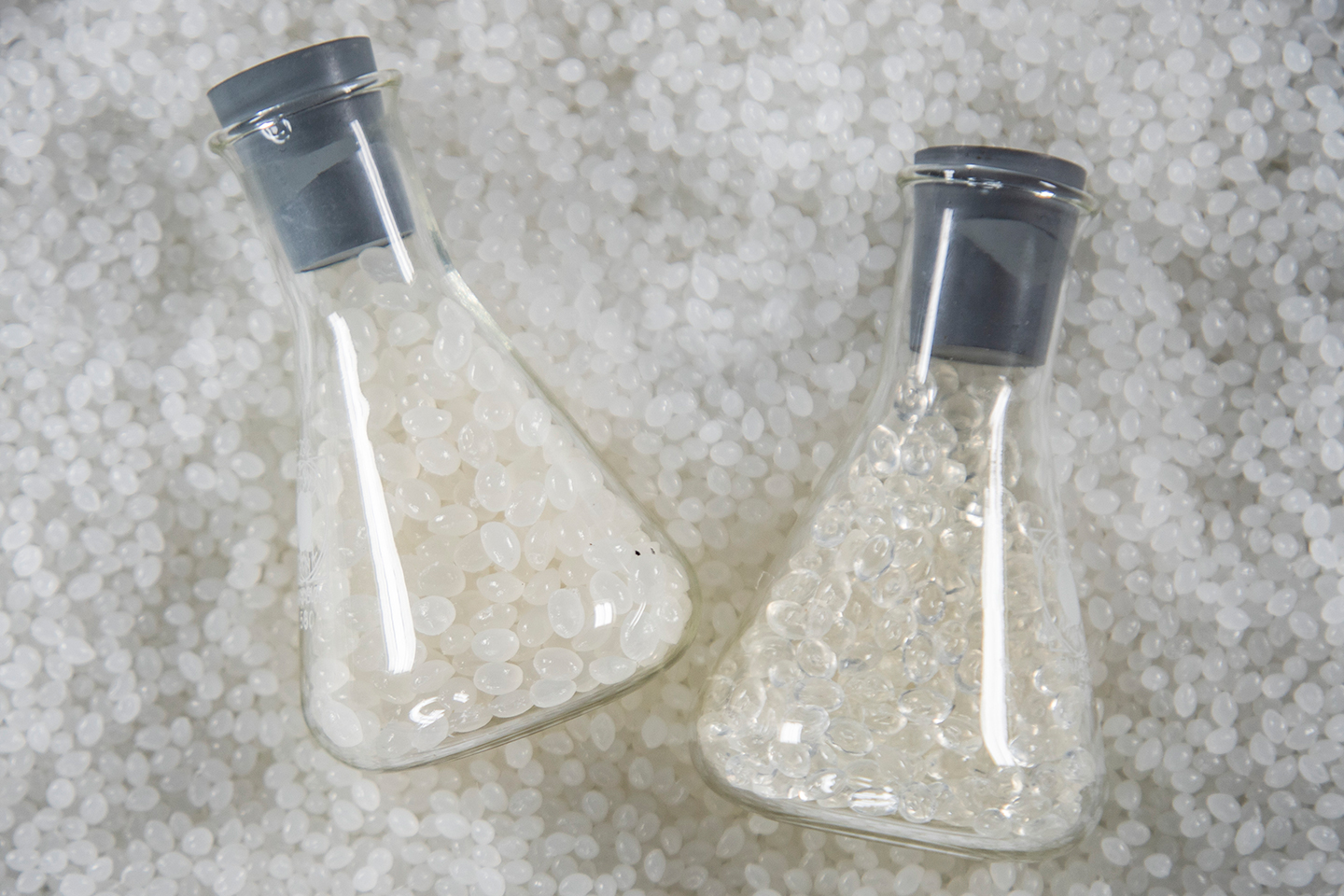

The foundation for this is an innovative solvent-based recycling process specifically designed for plastics from electronic waste. The waste plastic is dissolved using a single, low-boiling solvent – without the need for additional precipitants. In a subsequent drying step, the moisture content of the plastic is reduced to below 0.2%. Contaminants such as brominated flame retardants (BFRs) and antimony trioxide (ATO) are efficiently removed through solid-liquid separation and filtration. The solvent is evaporated in a spray dryer, leaving the purified polymer behind.

This process enables the recovery of high-quality plastics, which can be reused in new applications – as demonstrated by the produced door frames. At the trade fair, we will showcase the individual process steps using original samples – from the initial material to the final component.

The EU funded project SURPASS has been developing in one of its case studies multilayered films for food packaging. The films are developed at Centre Technique Industriel de la Plasturgie et des Composites (IPC) using the mulitnanolayered technology, which enables the use of less compatibilizer.

Fraunhofer ICT has developed a decontamination process using supercritical CO2, to remove any intended or not intended substances, like odours, from their recyclate at EoL.

At the K-fair we present our tray demonstrator made of the decontaminated recyclate of the previously manufactured and contaminated film.

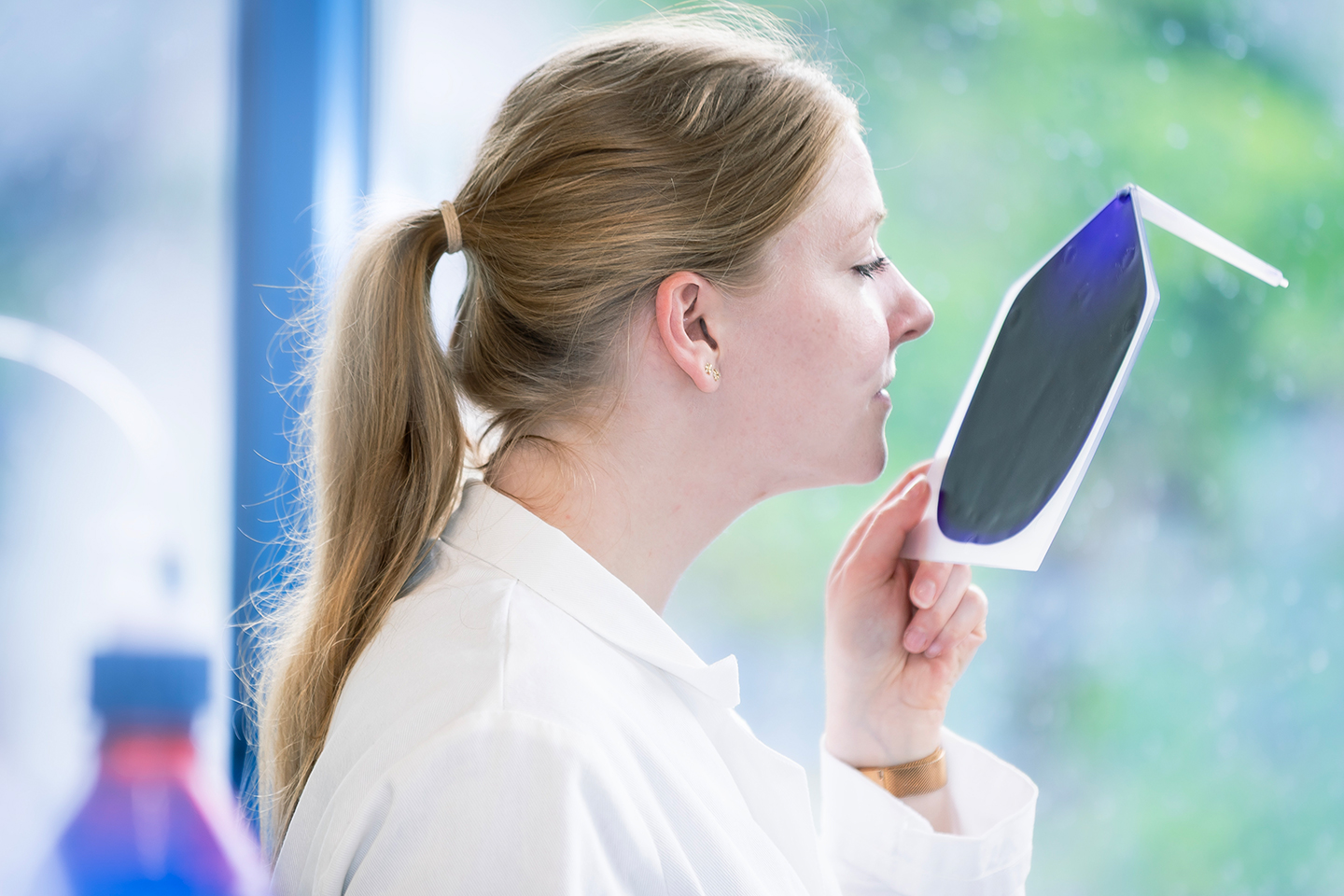

The Fraunhofer ICT develops processes and material concepts with which low-odour and low-emission recyclates can be produced - a key prerequisite for the high-quality use of recycled plastics.

Already in the compounding step, processes such as extractive extrusion and stripping enable the targeted removal of volatile components such as residual monomers, degradation products or formulation emissions. The result is odor-reduced granulates with improved purity and increased processing stability.

In addition, functional additives and multi-layer barrier structures are used. The latter were developed in the Fraunhofer Cluster Circular Plastics Economy CCPE together with other Fraunhofer Institutes. Additives suppress the outgassing of odor-active molecules, while a co-extruded skin made of virgin material with an integrated additive function effectively shields the contaminated recyclate in the core. In this way, the additive requirement can be reduced and a defined, homogeneous material surface can be achieved at the same time.

The integrative measures offer approaches for improved emission and odor reduction while at the same time maintaining the mechanical and functional properties of the recyclate. The Fraunhofer ICT is thus creating the basis for the sustainable and large-scale use of polymer recyclates in technically demanding applications.

Programmable materials are characterized by the fact that their material behaviour can not only be varied within wide limits due to their internal structure, but can also be designed responsively: Depending on the application and situation, the material then adopts different states and material properties initiated by external triggers. Programmable materials thus open up potential for new system solutions because they take over essential system functionalities such as movement patterns themselves, making additional system parts superfluous.

Various material samples and components will be on display to make the idea behind programmable materials tangible. In particular, these are examples of materials whose mechanical behavior changes in a predetermined way when subjected to pressure, or which exhibit shape-morphing behavior, i.e. deform in an unusual way when subjected to mechanical stress.

Electrically conductive polymer composites combine electrical conductivity with the possibility of using the component design options and manufacturing processes of thermoplastics. Nevertheless, they require special care with regard to their internal structure, i.e. the distribution and orientation of the electrically conductive fillers, which is crucial for their properties

Examples of additively manufactured, molded and extruded components for use as bi-polar plates in redox flow batteries and additively manufactured electrode structures for electrolysis applications as well as capacitive sensors that can be equipped with a defined hierarchical structure are shown.

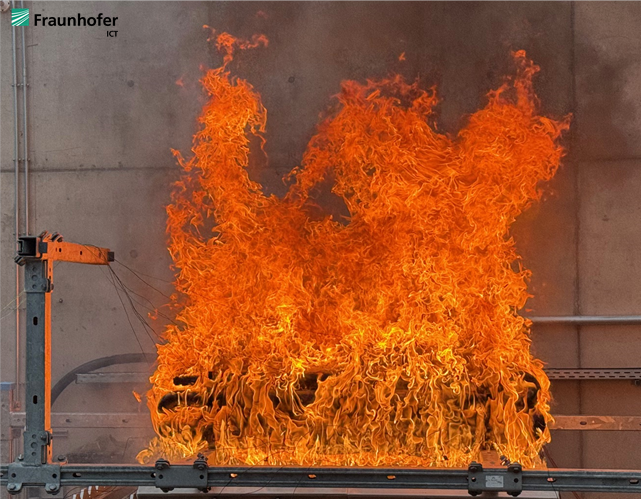

At Fraunhofer ICT, we are working on precisely this interface: We develop innovative material solutions that meet high fire safety requirements - and at the same time meet the growing demands for sustainability and resource efficiency.

At our stand, we will be showing selected demonstrators from ongoing research projects, including a novel vitrimer composite with integrated flame retardancy and recycling potential, powder- and liquid-based flame retardants for various plastic systems and exhibits on lightweight and structural materials for safety-critical applications - such as protective housings for battery and hydrogen tanks.

Short video sequences on the monitor provide an insight into material behavior, test methods and application scenarios - and show why modern flame retardants have to do more today than just meet standards.

Functional and refined

Compression-moulded components made from long-fibre-thermoplast (LFT) polycarbonate demonstrate a high surface quality – making them suitable for visible parts in automotive design. This is achieved by combining an amorphous thermoplastic polymer with an optimized processing route: the polycarbonate semi-finished product is compounded on an LFT-D-ILC line and directly moulded in a mirror-polished tool.

This approach overcomes a common challenge of LFTs: shrinkage and fibre imprint typically com-promise visual properties. By carefully selecting both material and process, a solution has been de-veloped that enables Class A surfaces made from LFT-D.

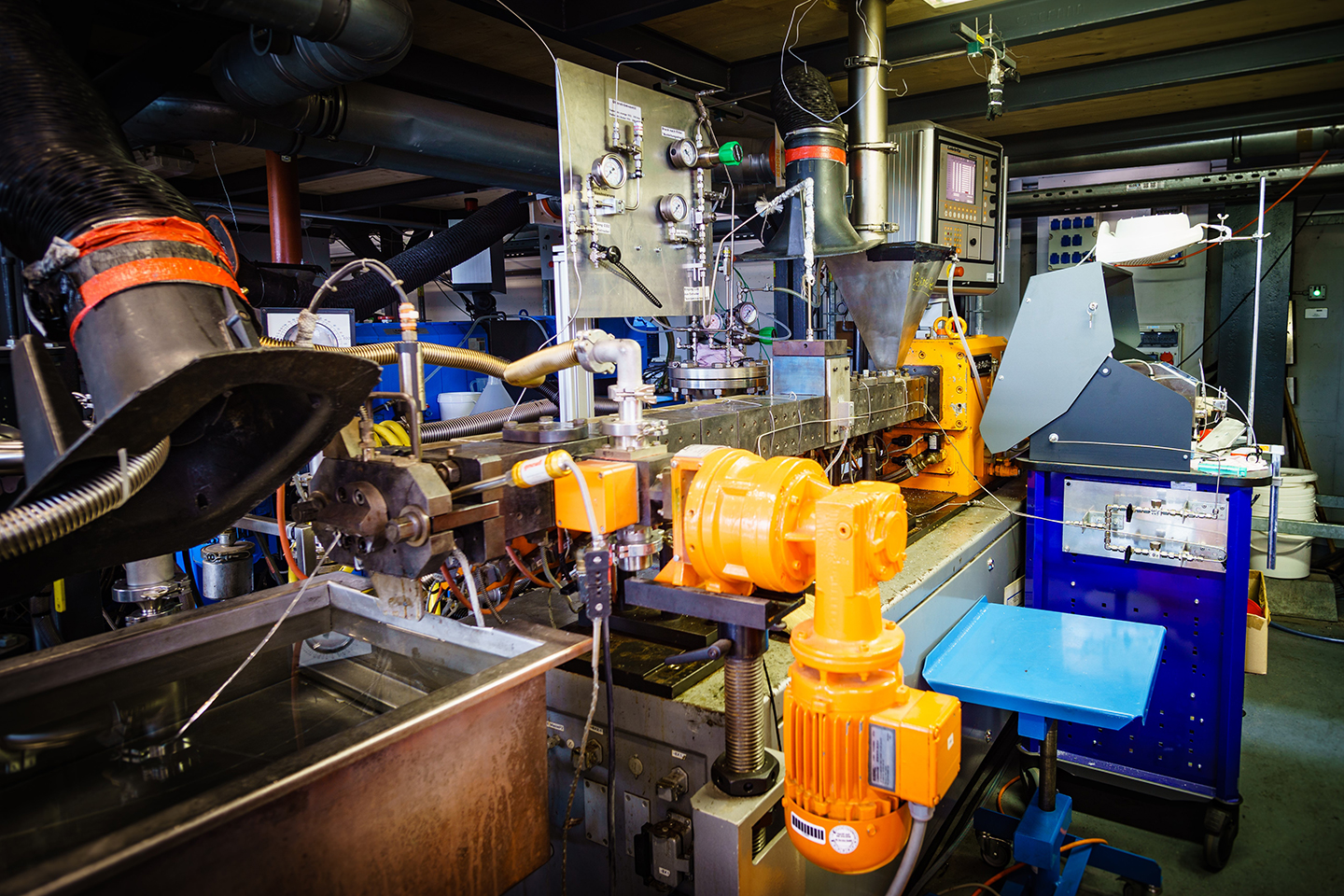

Switching from petroleum-based components to renewable alternatives in an established reactive extrusion process is a promising approach for the production of environmentally friendly thermoplastic polyurethane elastomers (TPU).

Fraunhofer ICT has many years of expertise in the field of reactive extrusion and a holistic understanding of the interactions between chemical reactions and the material flow within an extruder. This includes knowledge of the effects of heat and shear on polymerization and subsequent melt processing. Our inline process analytics implemented on the extruders (spectroscopy, rheology, etc.) as well as comprehensive data acquisition and evaluation enable highly efficient material and process development.

New bio-based polymer formulations have the potential to replace established petrochemical plastics in the medium to long term. However, a major obstacle to the use of these polymers is often their comparatively low temperature resistance. A proven strategy for improving these properties is the targeted stereocomplexation of PLA.

Together with partners, we at Fraunhofer ICT develop tailor-made stereocomplex PLA formulations for various applications such as injection molding, melt spinning processes and foaming technologies. The formulations are adapted according to the intended area of application, be it in the construction sector, the automotive industry or the textile industry. Thanks to the versatile processing possibilities of stereocomplex PLA, so-called monomaterial design components can be realized in which PLA is used in different material morphologies in the individual components. We successfully developed components, such as sandwich structures based entirely on PLA, which impress with high recyclability.

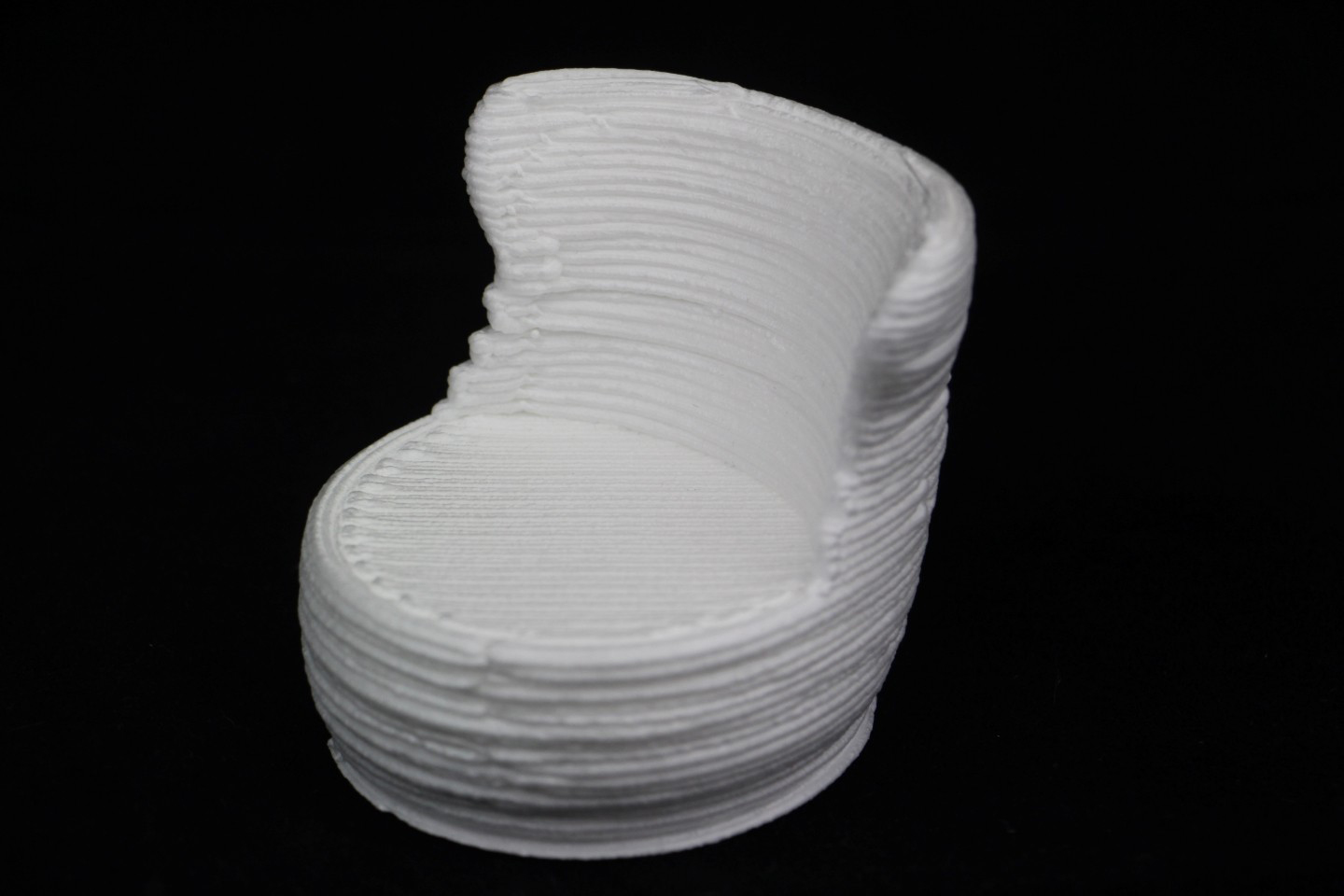

The physically loaded 3D printing filaments developed at Fraunhofer ICT are ideal for producing 3D printed structures with a very low density. The optimized polymer formulation and the precisely coordinated loading process enable targeted foaming in the 3D printer. The foam density can be controlled over a wide range by adjusting the process parameters

These innovative filaments can be processed on conventional filament-based 3D printers (FDM) without the need for a special hardware upgrade.

This process combines the advantages of foam technology and additive manufacturing, providing a straightforward approach to the production of molded foam parts. The advantages include the fast printing of large-volume components, the production of customizable moulded foam parts and the ability to produce graded components.

Today more than ever, industry and society are focusing on materials with high performance and resource efficiency as well as sustainable production methods. Foam materials such as bio-based foams made from PLA or those made from recycled materials such as recycled polystyrene make an important contribution to conserving raw materials.

Innovative foams made from technical thermoplastics, such as polyamides, also enable the development of new fields of application that could previously only be served by heavier, more material-intensive solutions.

Foams not only reduce the CO2 footprint of products during production due to their low material usage. Due to their special properties, such as excellent thermal insulation and low density, they also make a significant contribution to saving resources during the use phase. Examples of this are the reduction of heating and cooling energy in buildings or the energy savings in cars due to the reduced weight.

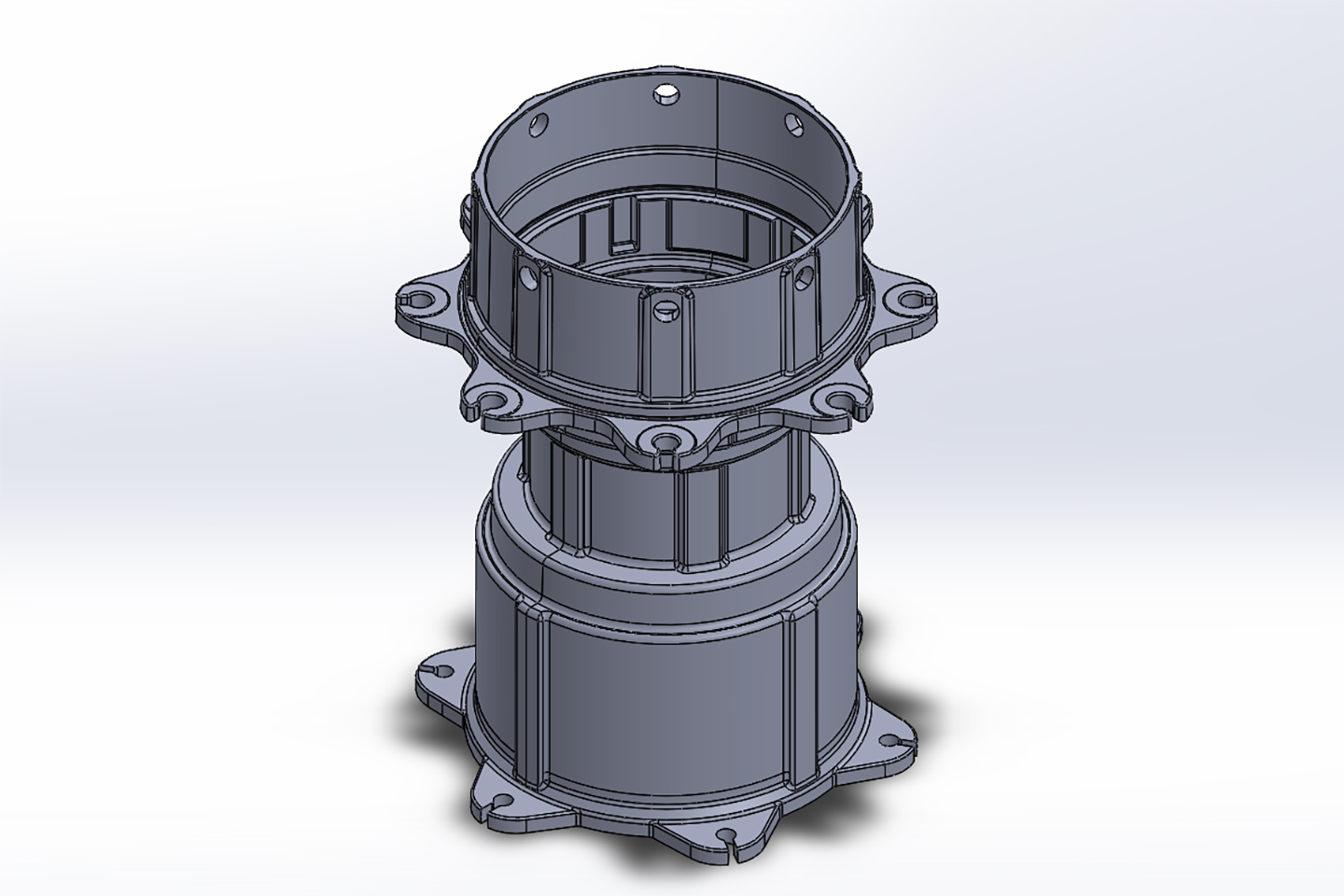

Lightweight, precise, and developed with series production in mind

A high-precision housing has been developed for the servo-electric drive of an aircraft door, enabling cost-efficient, as-moulded series production without any post-processing. Manufactured from carbon fibre reinforced polyphenylene sulphide (PPS-CF), the component serves as a structural carrier and integrates key elements of the actuator system: it houses both the stator and rotor of the electric motor as well as the planetary gear set, forming the core of the electric door drive.

To reduce production costs and simplify assembly, the housing is designed so that all functionally relevant bearing and fit surfaces – particularly for the motor stator and gear bearings – are directly formed in the injection moulding tool.

The concept combines functional integration with high dimensional accuracy and supports reproducible, economical production for safety-critical applications in the aerospace sector.

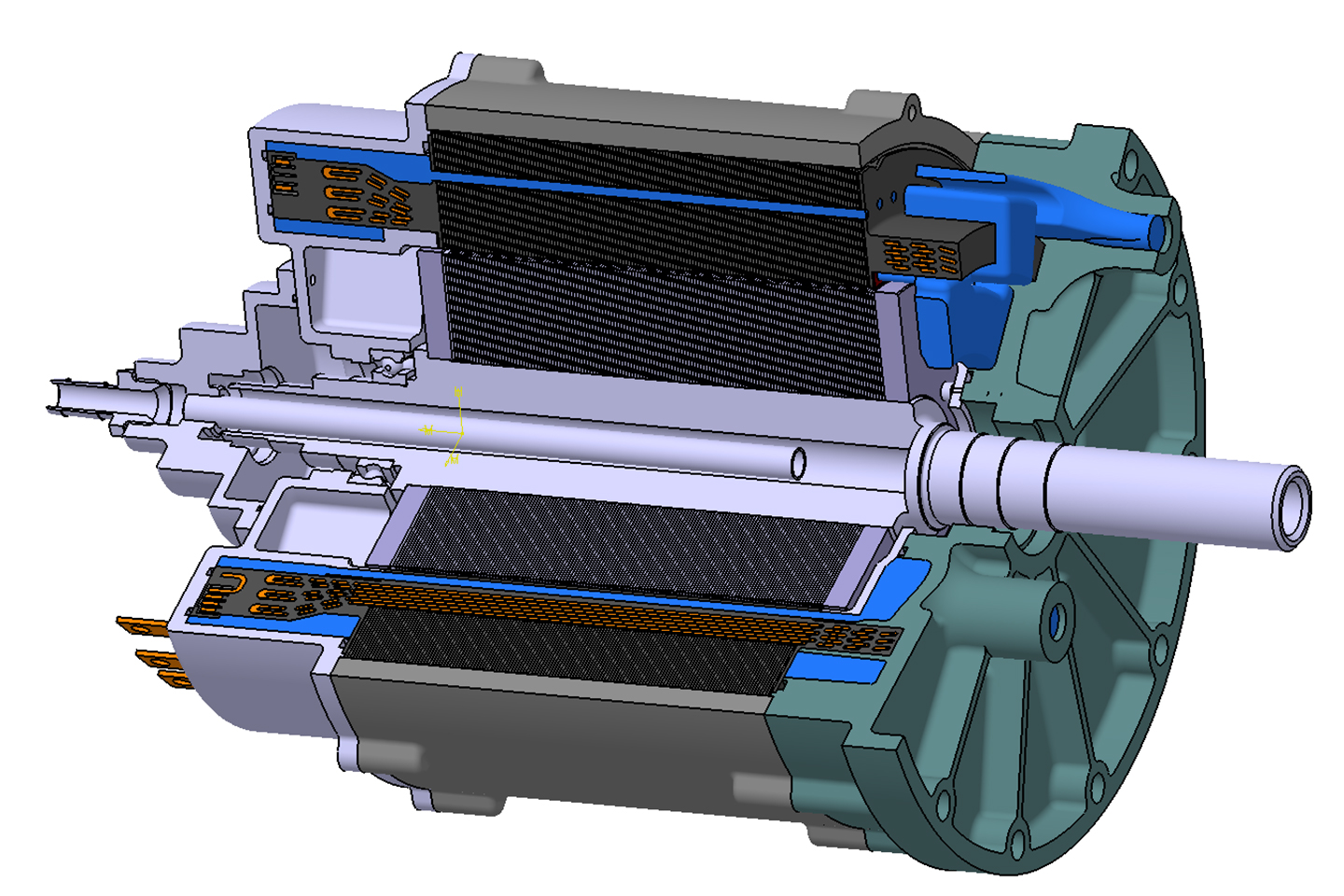

In the PerKuel research project, an innovative electric motor has been developed with an exceptionally high continuous power-to-weight ratio of ≥ 6 kW/kg – a decisive step toward lighter and more efficient drive systems for electric mobility. This is made possible by significantly improved cooling, which reduces the gap between continuous and peak power. At the same time, the overall weight of the motor was reduced by approximately 30%.

This result was achieved through a production-ready manufacturing concept featuring integrated cooling channels directly within the stator. The stator is produced using the transfer molding process from highly thermally conductive reactive molding compounds. Direct cooling with a water-glycol mixture ensures highly efficient heat dissipation. The concept is further enhanced by a lightweight plastic-metal housing. For the first time, the process quality is monitored acoustically. In addition, recyclability and CO₂ equivalents are evaluated as part of a life cycle analysis.

The PerKuel project demonstrates how innovative plastic technologies can actively contribute to the transformation toward climate-neutral mobility – while strengthening the international competitiveness of the German automotive industry.