In this research group, gas generator propellants and explosives are developed for defense and civil applications. Research topics include airbag applications, underwater rescue systems, insensitive high-performance explosives, plastic-bonded explosives charges and underwater explosives.

Gas generators, pyrotechnics and explosives

Gas generators and pyrotechnics

At Fraunhofer ICT, gas generator propellants are developed for defense and civil applications. Examples include base bleed propellants for gun ammunition, extruded tube gas generators for airbag applications and cold gas generators for underwater rescue systems.

Spectrum

The development of gas generator propellants at Fraunhofer ICT caters for a wide range of applications. Examples that demonstrate our specific experience and material developments in this area include:

- development of standard gas generator propellants based on ammonium nitrate and triaminoguaninium nitrate (TAGN) with inert and energetic binders,

- composite propellants for airbag applications, processed by extrusion or in a casting process,

- dual chamber system with integrated propellant and cooling agents to generate cold gas,

- gas generator propellants based on new energetic compounds such as guanylurea dinitramide (GUDN, FOX12) with high gas yields ≥ 1100 Nl/kg and exhaust gas temperatures ≤ 250 °C after release (70:1).

Types of gas generators and their properties

Different types of gas generators, composite propellants, extruded gas generator propellants and cold gas generators are developed and characterized. Composite propellants are molded or cast in pre-prepared insulation jackets. Extruded, rapid-burning, cord-type gas generator propellants, with a waste gas largely free of hazardous substances, are used for the inflation of tube-shaped bags up to 1 m long in 10 ms. Cold gas generators with AN propellants and cooling agent granules in a dual chamber system deliver gas volumes between 800 and 6000 l at end temperatures of 70 to 120 °C over 12 s.

Applications

- Base bleed propellants to increase the range for 120 mm or similar gun ammunition, based on composite propellants

- Gas generators with a high gas yield ≥1700 l/dm³ and a low exhaust gas temperature < 250 °C (after release) are applied in hydraulic and control systems

- Gas generators for airbag applications, with a waste gas sufficiently free of hazardous substances, high temperature and environmental stability (stability of 400 h at 130°C)

- Cord gas generators that can inflate cord-type bags within milliseconds, for head and side airbags in automotive construction

- Cold gas generators with a working time of up to 20 s and exhaust gas temperatures below 100 °C are used for life rafts, safety bags, emergency sealing, hydraulic closing, opening, lifting and inflation devices as well as for emergency shelters and open area systems.

Explosives

Using new energetic components, formulations for explosives with a higher performance and lower sensitivity than existing products are being developed, produced and characterized. Examples include compression molded, cast plastic-bonded explosives or melt-cast explosives for application in underwater explosives or enhanced blast explosives.

Computer-based optimization

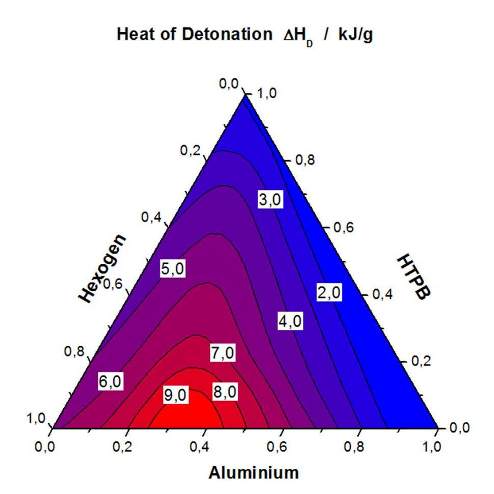

The developments and optimizations are supported by calculations using the ICT Thermodynamic Code and the program Cheetah 2.0, for example in calculating the heat of detonation as a function of the composition.

Process variants in the manufacture of explosives

- Charge production via compression molding - Hydrap press, pressing force 1250 kN, flexible choice of pressing process, one or two-sided pressing

- Casting of TNT charges - Casting unit for processing of up to 8kg TNT

- Casting of plastic-bonded charges - Thermostatic horizontal and vertical mixer with higher shear force for processing highly viscous masses in batch sizes of 50g to 8kg

- Casting equipment - Evacuable casting unit

Characterization methods

The newly-designed explosives charges are tested in the detonation chamber. In addition, safety tests are conducted according to the standardization agreement of the NATO (STANAG). Important characteristic parameters include:

- Brookfield viscosity

- Friction and impact sensitivity

- Density

- Detonation velocity

- Shock sensitivity

Our offer

The development of formulations and the manufacture of explosive charges according to customer specifications.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT