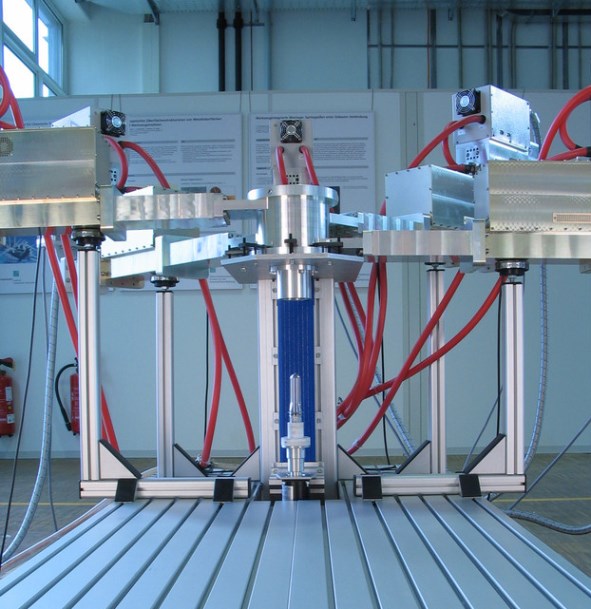

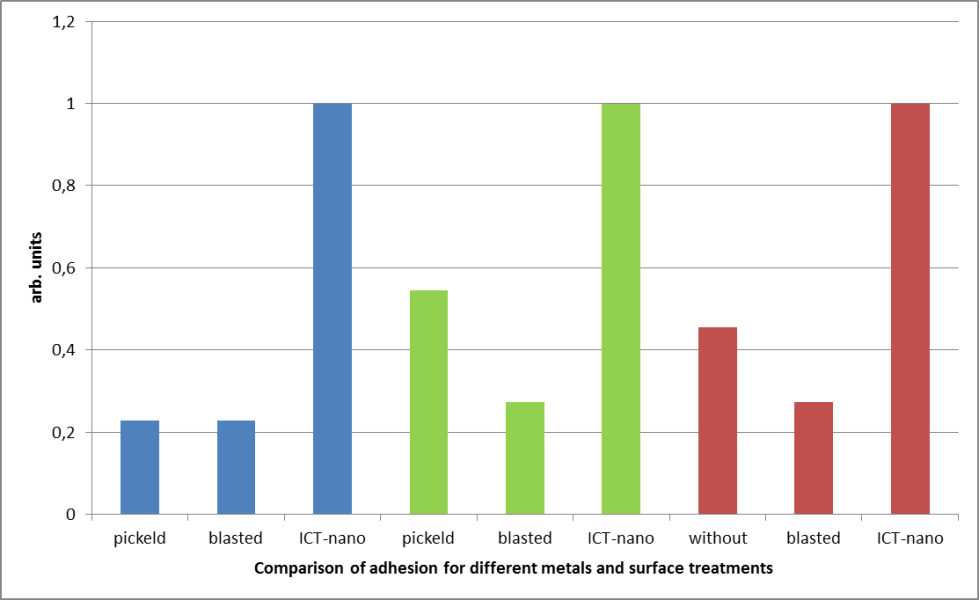

Fraunhofer ICT's competences in the area of microwave and plasma technology go far beyond simple processing technologies. They include the development of production units and measurement technology, accompanied by numerical simulation of the electromagnetic field and the resulting heating or plasma formation. Particular attention is paid to the reproducible and controlled application of microwaves. Plasmas generated with microwaves can be used for the cleaning, modification or coating of surfaces (PECVD).

Microwave and plasma technology

Heating of plastics with microwaves

Microwaves are non-ionizing electromagnetic waves, and are absorbed by polar, magnetic or poorly electrically conductive materials throughout their entire volume. This enables the materials to be heated independently of their thermal conductivity.

Our offer

- Measurement of the temperature- and frequency-dependent dielectric function

- Development and optimization of microwave units for thermal processes

- Development of processes using microwaves

Microwave-generated plasma-assisted chemical vapor deposition

Plasma-assisted chemical vapour deposition PECVD can be used to introduce a thin, functional layer onto the surface of various materials. This coating significantly improves the properties or usability of the component. Microwaves generate plasmas that enable very high coating rates.

Our offer

- Development of coating processes with microwave-generated plasmas according to customer specifications

- Evaluation of specific product properties with appropriate test procedures

- Upscaling to the construction of demonstrators

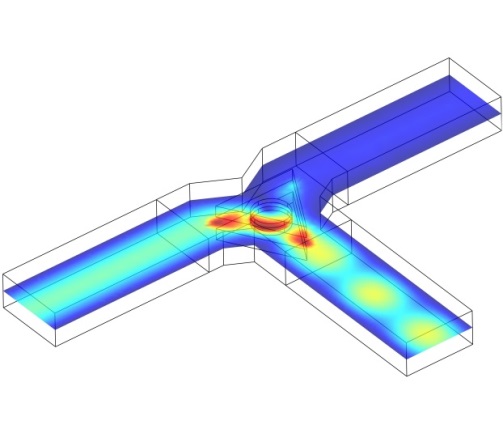

Simulation

Modern FEM software packages enable numerically-consistent simulation of electromagnetic fields and the associated heating or plasma generation. The simulation supports and accelerates the development of production units and processes in the area of microwaves and plasmas.

Our offer

- Electromagnetic field simulations of microwave applicators

- Optimization of applicators through simulation

Sensor and measurement technology

Microwaves are well-suited to process monitoring and control. Non-destructive measurements can be carried out to determine the degree of polymer cross-linking. The concentration and agglomerates and the concentration of nanoparticles can also be measured inline in the extruder.

We also have a fiber optic measuring device for continuous spatially resolved temperature and strain measurement along the fiber.

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT