Competence in polymer technology and composite materials

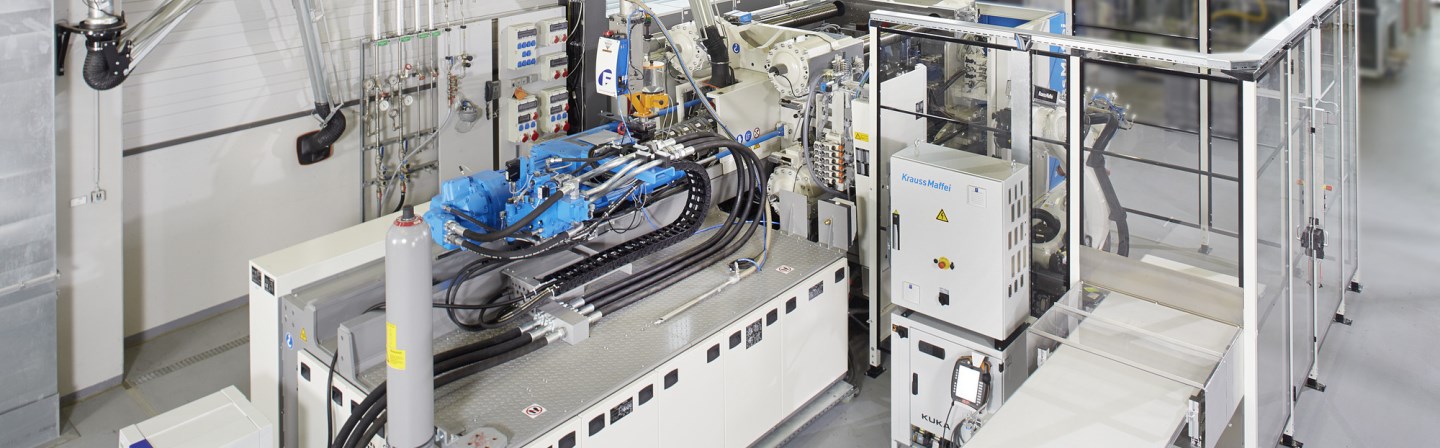

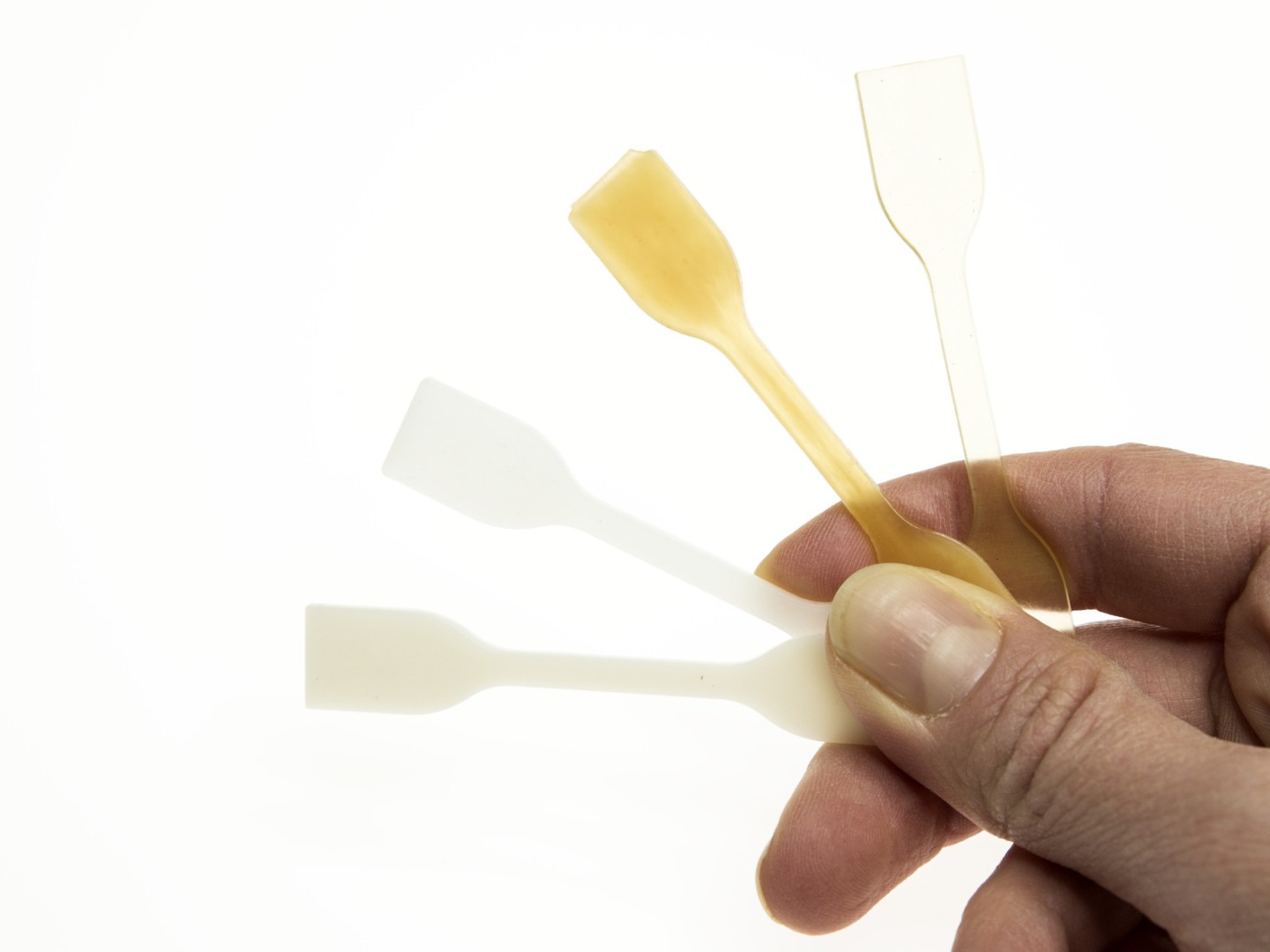

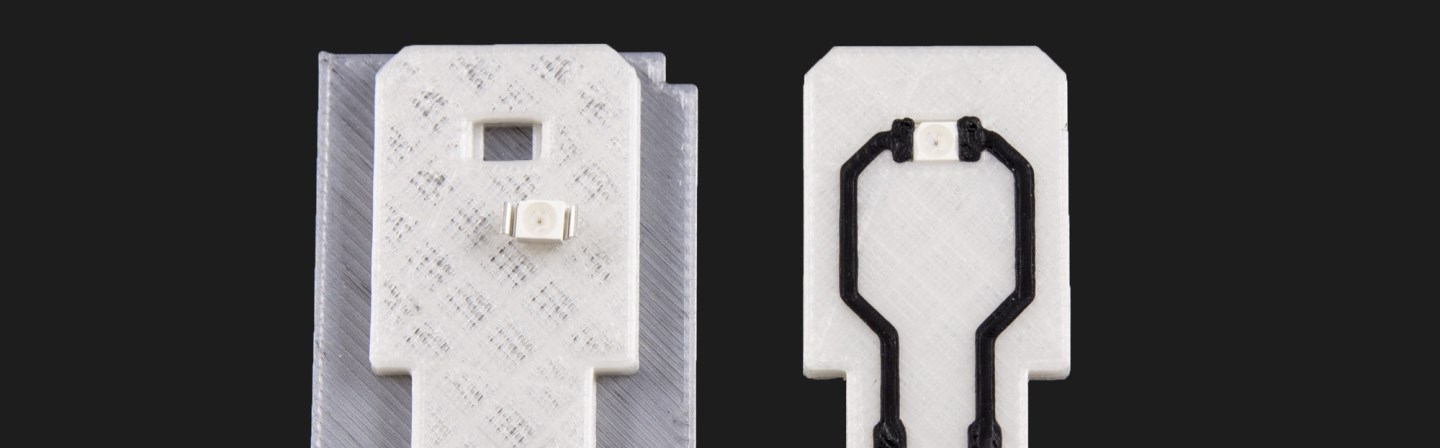

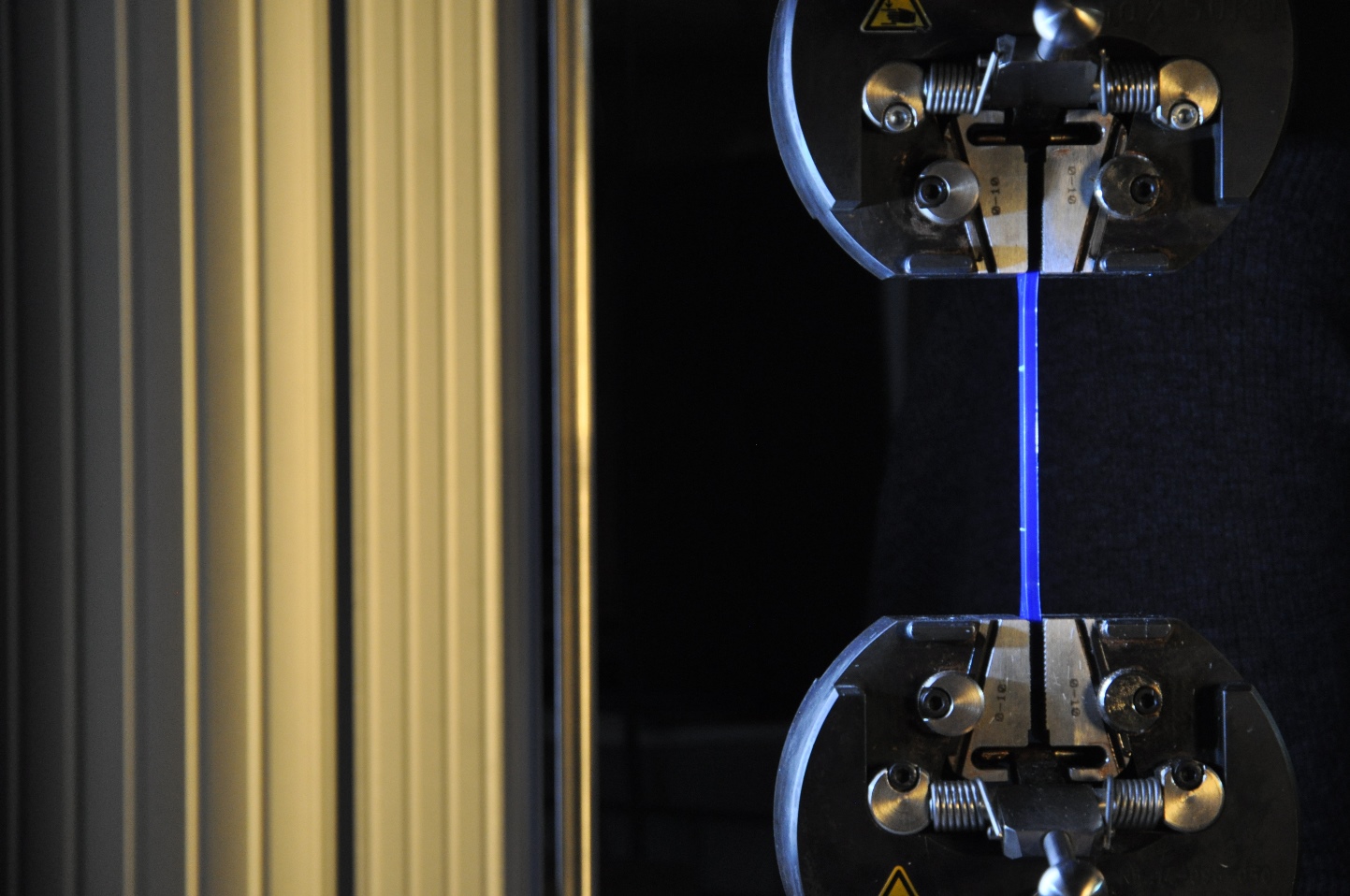

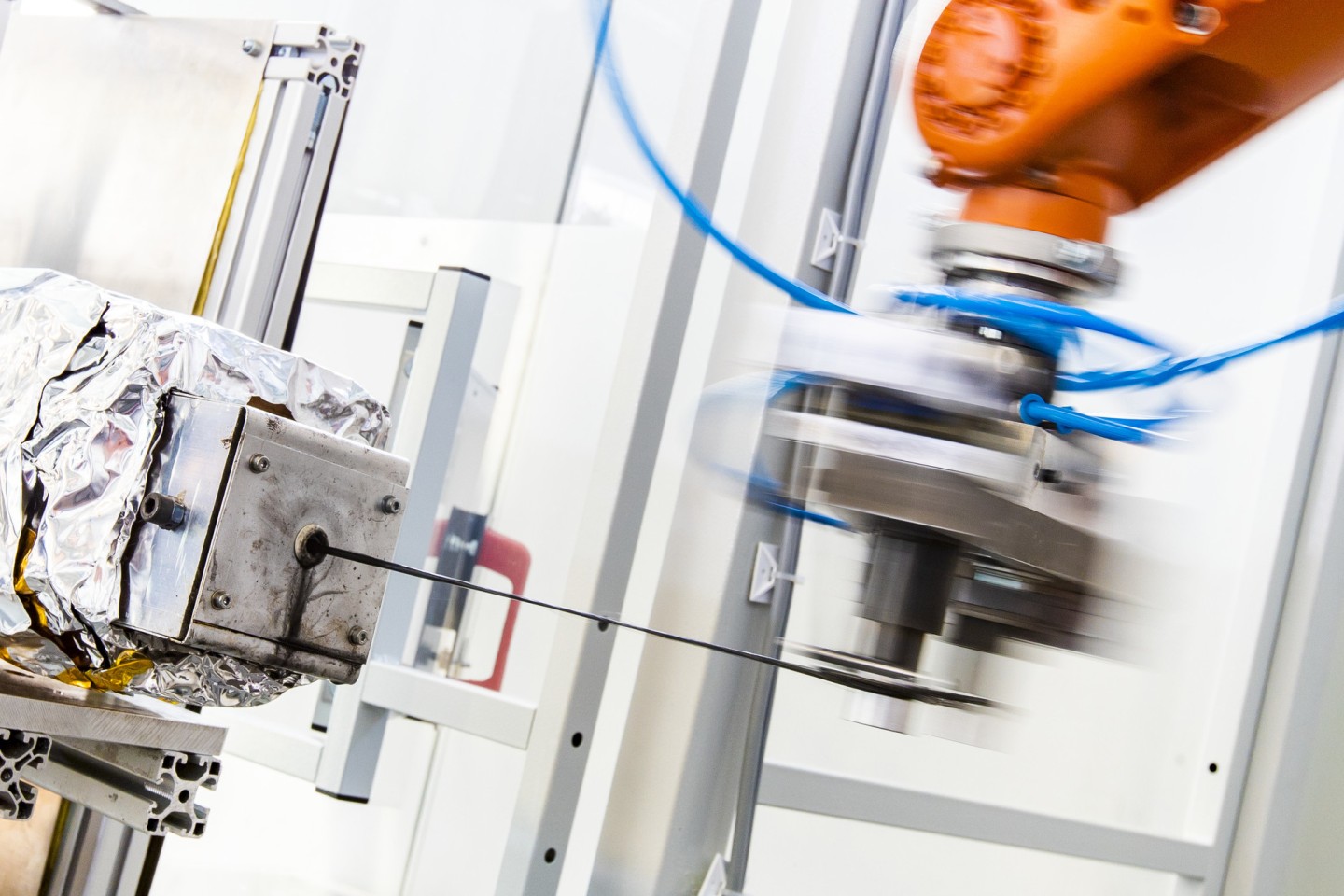

Material and process innovations provide the impetus for the development of advanced products. Long-standing experience in material and process development makes our institute a competent partner for application-oriented research and development in polymer and composite material technology - from the initial idea and the concept development through to the manufacture of prototypes.

We develop materials, processes and methods for our customers in the automotive, aerospace, construction, packaging, toy and leisure industries. In addition to individual topics from and along the value chain, we also provide solutions for long-term social challenges, in particular sustainable mobility, the circular economy, hybrid lightweight construction and the digitalization of process chains.

Our research approach is based on the following strategic topics: Sustainability, flexible manufacturing technologies, artificial intelligence, lightweight construction and material innovation

Fraunhofer Institute for Chemical Technology ICT

Fraunhofer Institute for Chemical Technology ICT